Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Sandwich Panel

Rock Wool Sandwich Panel

24Oct, 2022

The core material of stainless steel rock wool color steel sandwich panel is a kind of rock wool sandwich panel made of basalt and other natural ores as the main raw materials, which is melted into fibers at high temperature and solidified by adding an appropriate amount of binder.

Stainless steel rock wool color steel sandwich panel is suitable for thermal insulation and sound insulation of industrial equipment, buildings, ships, etc. At the same time, it is applicable to the ceiling and partition of houses, electronic clean rooms, purification rooms, explosion-proof and fireproof workshops.

The strength of stainless steel sandwich panel and rock wool sandwich panel in one body is three times higher than that of ordinary plane color steel sandwich panel. The stainless steel rock wool sandwich panel is connected to the roof truss with hidden self drilling screws, which does not damage the exposed part of the color coated panel and extends the service life of the color steel sandwich panel. The connection between plates adopts the button cap type, which is convenient for construction and improves the efficiency. The biggest feature is that it is not easy to seep water.

The installation accuracy of stainless steel sandwich plate: the perpendicularity of the facade is 2mm, the flatness of the surface is 3mm, and the straightness of the joint is 0.5mm. During installation, the technical manual provided by the manufacturer shall be strictly followed.

Use of weather resistant adhesive

While fixing the edge closing plate and flashing plate, it must be caulked and sealed with weather resistant adhesive to prevent gas penetration and rainwater leakage. Note:

1. Fully clean the gap between plates, ensure that the bonding surface is clean and dry.

2. In order to adjust the depth of the seam and avoid sticking glue on three sides, the seam is filled with PVC foam material.

3. After glue injection, the surface of glue joint shall be smoothed to remove excess glue.

4. Pay attention to curing after glue injection. Before the glue is fully hardened, do not touch dust and scratch.

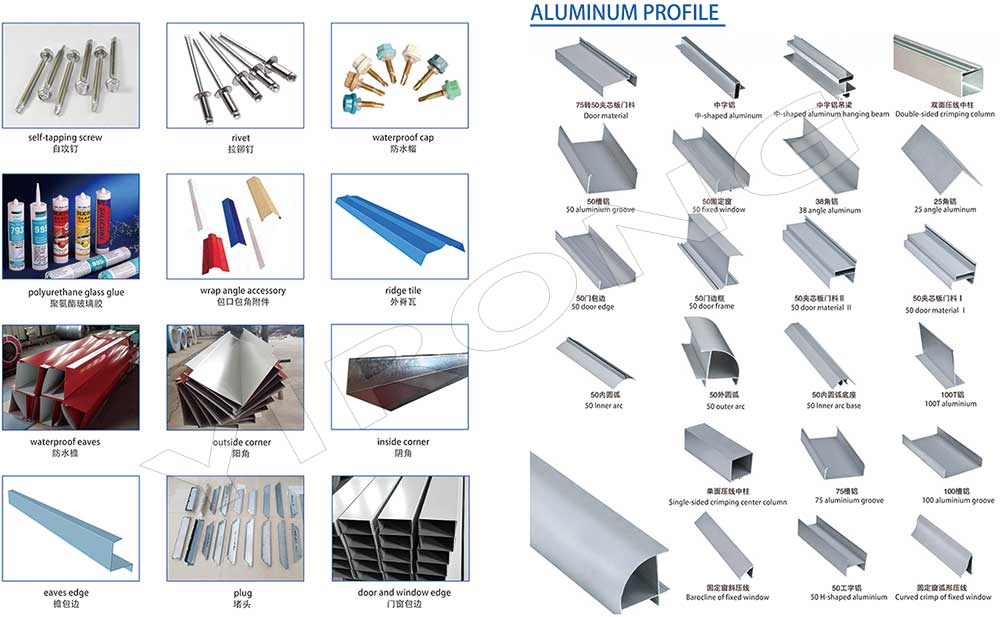

If you purchase metal sandwich panels from Yirong Company, we will also provide some accessory products, including self tapping nails, rivets, waterproof caps, polyurethane glass glue, mouth and corner accessories, outer ridge tiles, waterproof eaves, external and internal corners, eaves edging, plugs, door and window edging, purified aluminum profiles, etc.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged. And all the structure components, panels, bolts and sorts of accessories will be well packed with standard package and it is suitable for ocean transport.

1. Inspection: 50% inline inspection and 100% full final inspection, make sure all output w/o any mistake.

2. Packing: Per customer's requirements or per product sizes, full protection packing.

3. Shipping: Per customer's requirements or per container sizes.

4. Unloading: We package it as a whole and can be easily pulled out at once with a forklift, which is very convenient.