Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

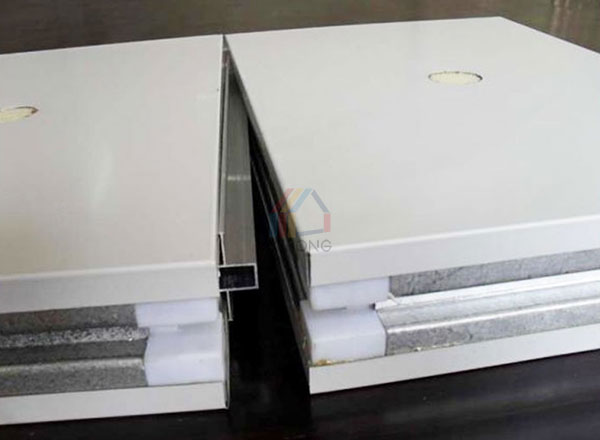

Manual purification board is a new type of material with good thermal insulation and fire resistance. Now it is widely praised by the industry, has been used in many industries, and has won praise from everyone. Some people wonder why more and more people like to use this material now, then the color steel sandwich panel manufacturer will come to show you the reason.

Relevant properties of handmade boards

1. High strength: High strength steel plate is used as the base material (tensile strength 5600KG/CM) plus the most advanced design and roll forming, which has good structural characteristics.

2. Fire protection: The surface material and thermal insulation material of the color composite sandwich panel are non-combustible materials, which can fully meet the requirements of fire protection regulations.

3. Beautiful appearance: The clear lines of the profiled steel plate are as many as dozens of colors, which can meet the needs of any style of buildings and achieve satisfactory results.

4. Thermal insulation: The commonly used thermal insulation materials for this composite board are: rock wool, glass fiber wool, polyethylene, polyurethane, etc., with low thermal conductivity and good thermal insulation effect.

5. Durability: Various studies have shown that it has been widely used in foreign countries for more than 40 years. The shelf life of color steel plates treated with special coatings is 10-15 years. After that, anti-corrosion coatings are sprayed every 10 years, and the life of the plates can reach more than 35 years.

With the development of the times, the emergence of new thermal insulation materials has gradually changed the pattern of our building housing, making the building more tidy. The manual purification board has a stronger thermal insulation effect, and its production energy consumption is relatively low. In use, it has the effects of soil saving, land saving, environmental protection, waste recycling, heat insulation, heat preservation, and light weight of the old thermal insulation material. It also reduces the transportation cost of materials to a certain extent, reduces the construction quotation, and adds keel inside, the strength is 4 to 5 times larger than that of ordinary machine-made boards, and the applicability is wide. Because it is hand-made, it can be filled with various core materials, regardless of the strength of the core material.

The market's requirements for energy saving, consumption reduction and environmental protection indicators of building materials products are also getting higher and higher. With the development of energy saving and environmental protection, the new environmentally friendly handmade board material has become a hot product. Therefore, it is unique in the new thermal insulation material.