Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

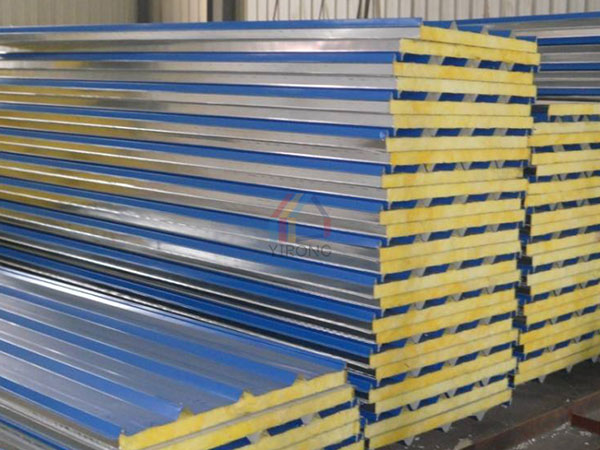

Nowadays, the roofs of many steel structure buildings often use sandwich color steel plates. When installing sandwich color steel plate, attention should be paid to the correct installation and construction methods.

1. Material entry

When the color steel sandwich panel material enters the site, the manufacturer should attach the original factory material inspection certificate. Before construction, check the specification, size and thickness of the color steel sheet and the slats, as well as the specifications, size, thickness and spare parts of various edge trimming materials. It is required that the appearance of the color steel sheet shall not have any scratches, stains, surface film wear, distortion, pollution, color difference, warping and other phenomena.

2. Lifting

Before the materials enter the site and set up the designated location, they must be placed in batches and categories. If they cannot be used immediately, they should be neatly stacked and covered with canvas or tape.

3. Hang the roof truss

Before hanging the color steel plate, a baffle must be set up to prevent it from slipping. When the sandwich color steel plate is hoisted to the roof truss, the color steel sheet is fastened on the suspender, and the oblique slings are added at both ends to keep it hoisted smoothly and slowly. After hanging on the roof, the color steel sandwich panel slowly descends, and after the crane personnel control the positioning (cornice baffle), it will be put down in sequence. All skin ribs must face upwards, the board surface should face the same direction (for easy installation, except for the female rib buckle), and should be fixed on the steel main frame with nylon ropes (not placed in the center of the bar).

4. Purlin installation

①Leveling: Check and level the purlin support before installation, check the flatness of the purlins one by one, and control the height difference between the installed purlins within the range of ±5mm.

②Elastic line: The support point of the purlin should be fixed according to the position of the support point required by the design, and the support point should be drawn with a line, after the installation and positioning of the purlin, it should be checked and accepted according to the purlin layout drawing.

③Fixing: Welding or bolting is carried out according to the design requirements, and the position is adjusted again before fixing, and the deviation is ≤±5mm.

④Acceptance: After the purlin is installed, the technical responsible person of the project will notify the quality officer or the supervision engineer for acceptance, confirm that it is qualified and transfer to the next process.

5. Laying and fixing of color steel plates

The laying sequence of sandwich color steel plate is generally from top to bottom, starting from the direction of the perennial wind tail.

①Roof: Take the gable side as the starting point, and lay it in order from left to right (or the same right to left). After the plate is placed, pull the alignment along the lower edge of the plate, and install each sheet according to the alignment, and check at any time to prevent deviation. The laying surface is fixed on the purlin along the center of each plate rib with self-tapping screws.

② Edge trimming: The lap joint of the trimming material on the roof (including the awning) must be fixed with aluminum studs and waterproof with water-stop glue. The self-tapping screw head and aluminum rivet head of the roof trimming plate must be prevented with water-stop glue. Ridge cover and cornice flashing (including gutter) must be covered with mountain-shaped foamed PE sealing strips. When the construction and fixing method of the edge-receiving board needs to be changed according to its on-site measurement, the drawing after confirmation shall prevail.

③Fixing: Arrange a fixed seat, fix it on the left side of the rib with self-tapping screws, then make a reference line on the purlin elastic ink line, and then fix the fixed seat in the same row; the rib of the block plate is aligned with the rib of the fixed seat, and press the card Check to see if it is properly snapped. Fasten the short arm of the fixed seat to the installed panel female rib, construct it according to the above method, and adjust it to be level. If the remaining space is greater than half of the board width, fix the board with a fixed seat, and cut off the excess part.

④Cleaning and waste transportation and disposal: In the area where the color steel sheet is laid, the metal scraps generated during iron cutting work and fixing screws should be cleaned up before the end of the work every day. The debris and debris (such as PVC cloth, steel belt, etc.) on the roof, ground and gutter should be cleaned up before the end of the day. After completion, the surface of the color steel sandwich panel should be checked, and the contaminated part should be cleaned.