Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

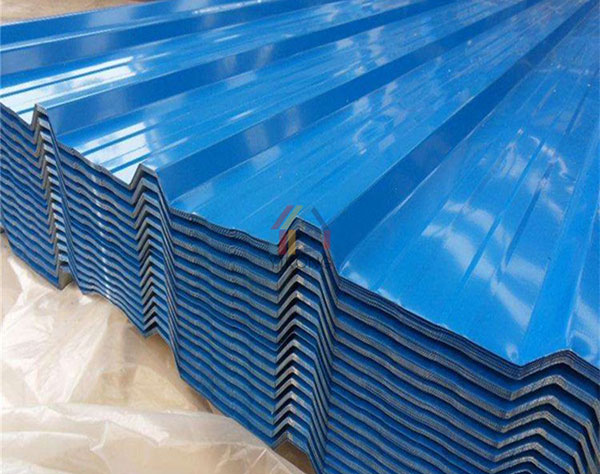

Color steel sandwich panel is a sandwich panel made of color steel plate and other raw materials. It has good antibacterial and antistatic effects, and is widely used in electronic devices, pharmaceuticals, aerospace and other fields. Under normal application, the color steel sandwich panel is not easy to corrode, but it is not sure whether it will corrode. If it is damaged by external force, it is likely to corrode. Let's talk about the reasons for the corrosion of rock wool sandwich panels.

Causes of Corrosion of Color Steel Sandwich Panels

First, the iron element of the sandwich panel, because of the long-term wind, sun and rain, the surface coating will inevitably be destroyed. Once the damaged site comes into contact with acids, alkalis and organic solutions, it will cause chemical changes and produce compounds, that is, rust. When the corrosion is more serious, holes will be produced.

Second, it is often rainy, and it will rust after a long time. Once it rains, the rust of the roof will be harmed by the oxidation and decomposition of the natural environment and strong acid and alkali rain. Precipitation will drip down the bluestone, causing erosion marks. Over time, large-scale erosion will occur on the roof.

Third, in addition, during the construction process, due to the negligence of the staff, the surface coating is damaged, and the sandwich panel may also be corroded. Therefore, during the construction of the project, the construction team should pay attention to the construction of the project and solve it with care to prevent damage to the surface coating.

In addition to the above factors, there are other reasons for the corrosion of color steel sandwich panels. If rust is found in the application, it should be properly handled to prevent the rust from expanding and avoid jeopardizing the service life of the sheet.