Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

There are many control and protection methods for metal corrosion. Among them, the method of preventing corrosion by isolating steel and external media by coating is more common in thin plates. These cover coatings are mainly divided into two types: metallic coatings and non-metallic coatings.

Alloy elements with better corrosion resistance such as aluminum-zinc alloy and zinc-aluminum-magnesium alloy are added to the surface of the steel plate (metal coating). It not only improves the life of the steel plate, but also prolongs the service life of the building, so what impact does the non-metallic coating have on the life of the steel plate?

Factors affecting the failure of coated steel sheets

Color coated panels used in construction are mainly affected by ultraviolet rays in sunlight, moisture in the air and harmful substances caused by industrial pollution, reducing their service life. The corrosion protection of architectural color coated products is a combination of plating, pretreatment films and coatings (primers, topcoats and backcoats). This combination is very important and directly affects its service life.

Corrosion failure process of coated steel sheet

Coating failure, coating failure and even steel perforation are the key corrosion processes. Therefore, increasing the thickness of the coating layer, and adopting a weather-resistant and corrosion-resistant coating layer is the most effective means to prevent the corrosion failure of the color coated sheet.

Types of Coated Steel Coatings

The coating layer is considered to ensure the durability and corrosion resistance of the building. Different uses can be achieved by choosing different platings, coatings and thicknesses to meet their service life.

The commonly used topcoat varieties of coil steel coatings are polyester (PE), silicon modified polyester (SMP), high durability polyester (HDP), fluorocarbon (PVDF); the varieties of primer and back paint are ring-shaped Oxygen (EP), Polyester (PE), Polyurethane (PU), etc.

Ordinary polyester PE

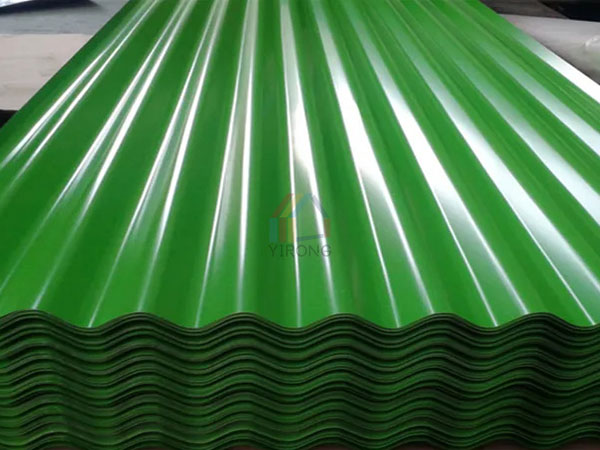

It is a product made of hot-dip galvanized sheet, hot-dip 55% aluminum-zinc sheet, etc. as the substrate, after surface pretreatment, coating one or several layers of paint on the surface, and then baking and curing.

Silicon Modified Polyester (SMP)

The traditional silicone modified polyester coil coating is modified with silicone resin and polyester resin cold-spliced to further improve the weather resistance of the silicone-modified polyester resin, so that the coating can achieve outdoor weather resistance for 20 years.

High Durability Polyester (HDP)

High-durability polyester (HDP) resins are synthesized with monomers containing cyclohexane structure to achieve the balance of flexibility, weather resistance and cost of resins. The absorption of UV light achieves high durability of the coating.

Fluorocarbon (PVDF)

PVDF fluororesin coatings started in the 1960s. After nearly 50 years of practical use, it has been proved that the weather resistance is very excellent. It is the best weather resistance among coil coatings at present. Fluoropolymers also have excellent weather resistance. High chemical stability.

PVDF resin has excellent UV resistance, so that the primer is not attacked by UV light, so the pigment used must have excellent weather resistance and chemical resistance, and can withstand 20-30 years of outdoor exposure. The chemical properties are relatively stable and suitable for long-term protection.

How to choose the type of color steel plate coating

The coating is considered to ensure the durability and corrosion resistance of the building, and different uses can be selected to meet its service life by choosing different coatings, coatings and thicknesses.

There are many kinds of color steel plate, and the performance indicators of different products are quite different. According to the needs of the end user, the design of the design unit and the processing conditions of the processing unit, it is very important to recommend the selection of the appropriate color-coated sheet.