Zhengzhou, Henan Province, China

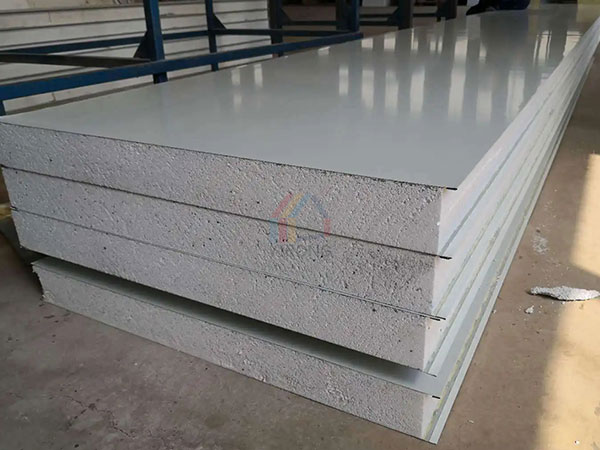

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Nowadays, people pay more and more attention to exterior wall decoration, and now almost every family will make exterior wall insulation boards when they carry out exterior wall decoration. Insulation board is a kind of heat insulation, heat preservation function. Many owners are not very clear about the construction method of external wall insulation board and the precautions for the construction of external wall insulation board. If you want to play a supervisory role in the decoration, you need to know more about the external wall insulation construction.

First, the base wall treatment

The base surface of the structural wall of the new construction must be cleaned, and the surface of the outer wall shall be free of contaminants such as oil, floating dust, dirt or other materials that hinder bonding, and the flatness and verticality of the wall shall be inspected. Check with a 2m ruler, the large deviation is not more than 5mm, and the excess part should be chiseled or repaired with dry powder mortar. For the energy-saving renovation of the old house, the original outer wall layer that is not conducive to sticking polystyrene boards should be thoroughly cleaned, and the defects should be repaired with cement mortar, and then the outer wall insulation construction can be carried out.

Second, measure the line

1. According to the building facade design and the technical requirements for external insulation of the external wall, the horizontal lines, vertical control lines, expansion seams and decorative lines of the external doors and windows are popped up on the wall.

2. Hang vertical reference steel wires at the big corners (inner corners, outer corners) and other necessary places of the building's outer wall. Horizontal lines are hung at appropriate positions on each floor to control the verticality and flatness of the EPS polystyrene board.

Third, paste the polystyrene board

1. EPS polystyrene board cutting: try to use 1200*600mm or 900*600mm standard size polystyrene exterior wall insulation board. If a non-standard size polystyrene board is used, it should be cut with a heating wire cutter or a wallpaper knife. The diagonal error is ±2mm, and it is processed according to the actual size required. The allowable deviation of the size is ±2mm, and the large and small planes are vertical.

2. Bonding mortar: use the finished bonding mortar for external wall insulation construction. The prepared bonding mortar is best used up.

3. Pre-paste 250mm wide bottom mesh cloth on the polystyrene exterior wall insulation board on both sides of the deformed suture.

4. Bonding EPS polystyrene board method:

①Hang vertical wires at the yin and yang corners of the outer wall, and level them with a level, at least 2 on each wall, and pay attention to make them the same size from the wall. When using segmented sticking, a horizontal line is placed on the starting layer, and the vertical control line is measured and popped out at the large-angle base layer with the theodolite, and a horizontal line is hung according to the vertical vertical line as the control line for pasting the polystyrene insulation board.

②The first layer of polystyrene sandwich panels is fully adhered to the outer wall, and the polystyrene external wall insulation panels of other floors are coated with a circle of polymer mortar around the board surface, 50mm wide and 10mm thick, with 50mm*50mm wide vent holes on the side, and the core of the board. The bonding points are arranged in a plum shape, with a spacing of 200mm and a diameter of 100mm. When non-standard size boards are used, the ratio of the application area of the adhesive glue to the area of the eps sandwich panel shall not be less than 1/3.

③ After wiping the bonding mortar, immediately put the board upright and paste it in place. When pasting, it should be squeezed gently and evenly, and the vertical level of the board should be checked at any time. The board is squeezed tightly with the board, and the polymer mortar is not applied to the joints. The eps polystyrene insulation board should be pasted up and down with staggered seams. After each board is pasted, the extruded mortar should be removed in time without leaving a gap between the boards. If there is a gap, it should be filled with a corresponding width of polystyrene sandwich board.

④The polystyrene insulation boards attached to the two adjacent walls at the yin and yang corners should be connected vertically and staggered to ensure the verticality of the board installation.

⑤Installation fixing parts: Drill holes with an impact drill on the pasted eps polystyrene sandwich panel, the holes should not be less than 30mm deep into the wall base, and the number is 2-3 per square meter, but each single polystyrene board should be drilled with an impact drill. Not less than 2. If the base layer is a concrete component, nylon plastic expansion pipe is used. If the base layer is ceramsite hollow block, special anchors are used.

Fourth, polystyrene board grinding

The uneven joints of the polystyrene exterior wall insulation board should be smoothed with coarse sandpaper, and the grinding action should be a gentle circular motion. After smoothing, use a brush or compressed air to remove debris.

Fifth, apply the glue

Use a stainless steel trowel to evenly spread a layer of plastering glue with an area slightly larger than a mesh cloth on the surface of the EPS polystyrene board, with a thickness of about 2mm.