Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Sandwich Panel

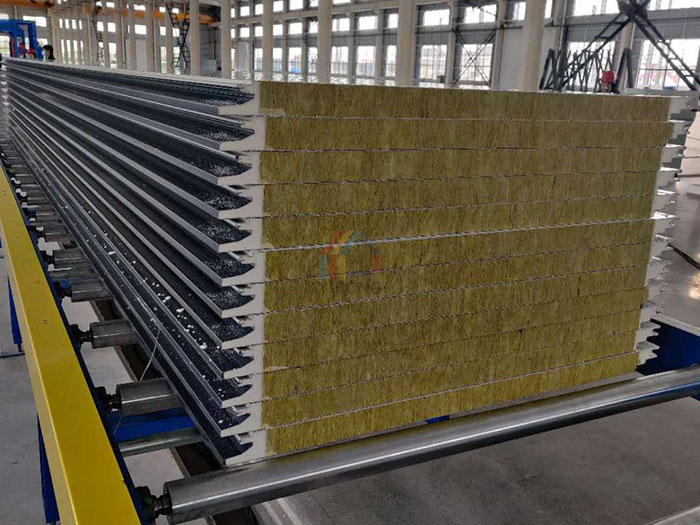

Rock Wool Sandwich Panel

15Jul, 2022

Polyurethane edge sealed rock wool board is made of non-combustible structural rock wool as the core material, with galvanized or galvanized color coated steel plate as the facing, both ends of the polyurethane edge banding, through the standard development of adhesive, the two form a mutual It is a high-quality energy-saving building board made of composite materials. It integrates fire prevention, thermal insulation, sound insulation and beautiful decoration, convenient installation, time saving and firm.

Polyurethane edge sealed rock wool sandwich panel has low thermal conductivity, good load resistance, high flexural strength, no water absorption, no decay, no moth and rat bite, good flame retardancy and large temperature resistance range. Using the physical properties and unique formula of polyurethane (PU.PIR), the polyurethane foaming agent is evenly sprayed on the color coated steel plates, so that the foaming agent is foamed between the color-coated steel plates into a three layer one-time molding polyurethane ( PU.PIR) color steel composite sandwich panel. This new light-weight building material is a good combination of color-coated steel plate and polyurethane, and is the development direction of light-weight building materials.

Features of Polyurethane Edge Banded Rock Wool Board

1. Sealing performance: Polyurethane double sided sealing rock wool sandwich panel adopts an assembly line production process, and uses the excellent waterproofness of polyurethane products to overcome the shortcomings of rock wool that is easy to absorb water and deliquescence, and effectively prolong the service life of the product in terms of physical properties.

2. Beautiful performance: The interface is designed according to European standards, the appearance is round and smooth, the board surface is flat and beautiful, the joints are tight, the strength is reliable, and the generation of cold and hot bridges is effectively prevented.

3. Good rigidity: Polyurethane double-sided sealing rock wool core material and two layers of steel plates are bonded into a whole and work together, plus the wave pressure type on the upper surface of the roof panel, its overall rigidity is much better than that of the rock wool sandwiched by the pressure plate ( glass wool) on-site composite panels. After the sandwich panel is fixed with the purlin by the connector, the overall rigidity of the roof is greatly improved, and the overall working performance of the roof is strengthened. If rock wool sandwich panel is selected, a larger purlin spacing can be used, which can save 1/3 to 2/3 of the purlin consumption.

4. Reasonable fastening method: The polyurethane double sided rock wool roof panel adopts the hidden button connection method, which avoids the hidden danger of water leakage at the joints of the roof panel and saves the number of accessories.

5. The fixing method is firm and reasonable: The polyurethane edge-sealed rock wool board is fixed with special M6 self-tapping screws and purlins, which can effectively resist external forces such as typhoons. The self-tapping screw is arranged on the top between the two panels of the roof panel, and a special waterproof structure is adopted to avoid the weak link of waterproofing.

6. Short installation period: Polyurethane edge sealed rock wool sandwich panel, since there is no need for secondary processing on site, can not only keep the surrounding environment clean and tidy. It does not affect the normal progress of other processes, and can greatly shorten the installation period of rock wool panels. The average daily installation area of sandwich panels is 600-800 square meters.

7. Anti-scratch protection: During the production process, the surface of the polyurethane double sided rock wool sandwich panel can be pasted with a polyethylene self-adhesive protective film to avoid scratches or abrasions on the surface coating of the steel plate during transportation and installation.

The advantages of polyurethane edge sealed rock wool board:

1. Excellent fire resistance: The raw materials, production process and formula used in the polyurethane edge-sealed rock wool sandwich panel make it have good fire resistance. Tests show that it has fire resistance above 1000°C. Polyurethane double sided rock wool sandwich panels have passed the inspection of GIOROANO S.P.A, an Italian authoritative inspection agency. According to International Organization for Standardization (ISO), British BS and German DIN standards, rock wool sandwich panels comply with fire protection standards M.I.14/09/61 Letter No. 91 and D.M. 30.11.83 request. The test results are as follows: 50mm thick polyurethane double-sided rock wool sandwich panel REI 30, 80mm thick polyurethane double sided rock wool sandwich panel REI 60, 100mm thick polyurethane double-sided rock wool sandwich panel REI 120.

2. Good thermal insulation performance: The thermal insulation performance of the polyurethane double sided rock wool sandwich panel is obtained according to the thermal conductivity of rock wool λ=0.043 W/m2 K and the corresponding proportion of the material calculated according to the thickness of the rock wool core.

3. Remarkable sound insulation and sound absorption effect: Polyurethane edge sealed rock wool board has a significant reduction effect on noise transmission, especially suitable for places where designated flights pass. In addition, the indoor sound caused by the impact of rain and hail on the roof steel plate of the building is also significantly reduced after the use of rock wool roof panels. Through the test, according to ISO 717/82 and UNI 8270/7 standards, a sandwich panel with a density of 120kg/m³ rock wool is selected as the core material, and the sound insulation effect can reach RW=29~30dB.

The rock wool sandwich panel also has excellent sound absorption effect, which can absorb sound in a wide frequency range. According to ISO 354/85 standard, the sound absorption performance level of rock wool sandwich panel reaches DELTA LA=15.7 dB(A).

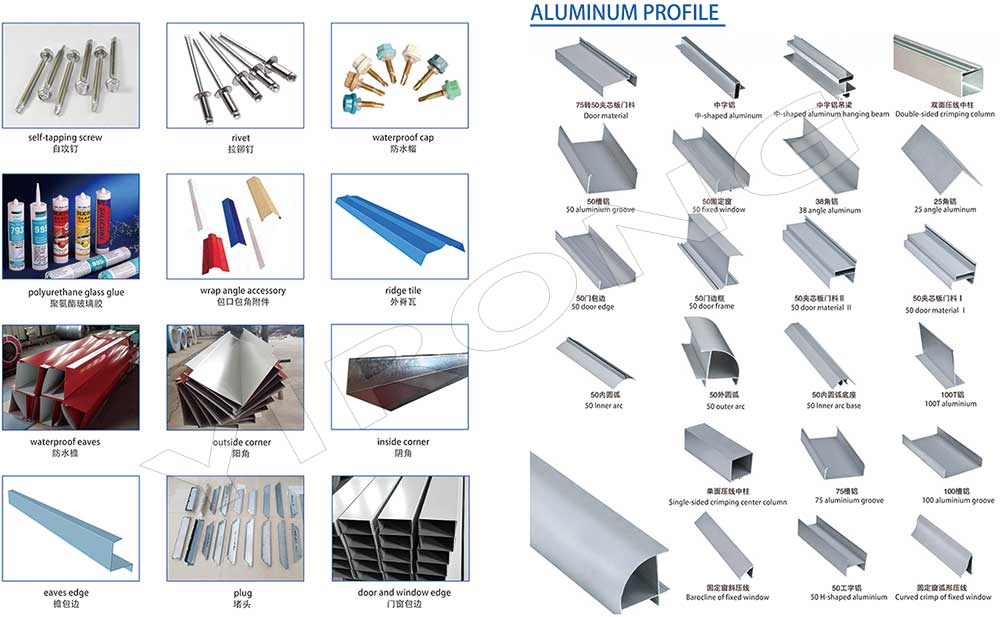

If you purchase metal sandwich panels from Yirong Company, we will also provide some accessory products, including self tapping nails, rivets, waterproof caps, polyurethane glass glue, mouth and corner accessories, outer ridge tiles, waterproof eaves, external and internal corners, eaves edging, plugs, door and window edging, purified aluminum profiles, etc.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged. And all the structure components, panels, bolts and sorts of accessories will be well packed with standard package and it is suitable for ocean transport.

1. Inspection: 50% inline inspection and 100% full final inspection, make sure all output w/o any mistake.

2. Packing: Per customer's requirements or per product sizes, full protection packing.

3. Shipping: Per customer's requirements or per container sizes.

4. Unloading: We package it as a whole and can be easily pulled out at once with a forklift, which is very convenient.