Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

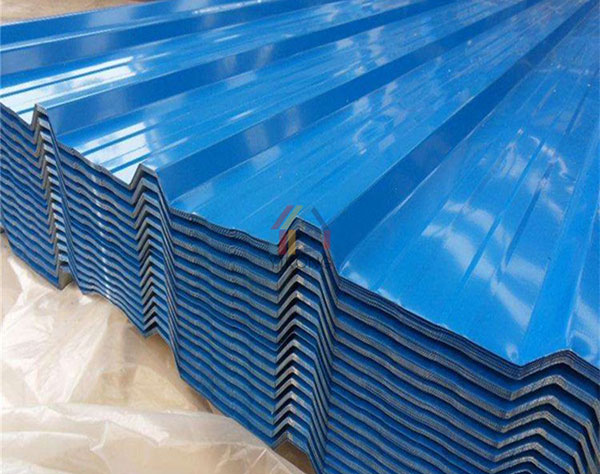

What is color steel plate?

Color-coated steel plate refers to color-coated steel plate, and color-coated steel plate is a kind of steel plate with organic coating. Color steel plates are divided into veneer and composite sandwich panels. It is widely used in the walls and roofs of large public buildings, public workshops, prefabricated houses, clean workshops and integrated houses.

Classification of color steel sandwich panels

Color steel sandwich panels can be divided into polyurethane (PU) color steel sandwich panels, rock wool color steel sandwich panels, glass wool sandwich panels, paper honeycomb sandwich panels, polystyrene foam color steel plates (EPS sandwich panels) ) different core materials.

Polystyrene (EPS) foam color steel plate, also known as foam color steel sandwich panel, is an organic material with the characteristics of thermal insulation, light weight and convenient installation, and has been widely used in recent years. The disadvantage is that the foam color steel plate is easy to burn and cannot meet the fire protection requirements.

Relevant information shows that polystyrene foam sandwich panels will soften and produce molten droplets when exposed to high temperature or open fire, accelerating the spread of fire. Because the ingredients contain cyanide and chlorine, they will emit toxic fumes, causing people to be poisoned and suffocated. The eps color steel sandwich panel spreads rapidly after a fire, and the combustion products are highly toxic, which can easily cause major property losses and casualties.

Polyurethane color steel plate is composed of upper and lower color steel plates and middle foamed polyurethane. It is one of the most widely used building materials in the construction industry. Many people often mistake the foam color steel plate for the polyurethane sandwich panel.

Rock wool color steel plate is a new type of fireproof board with the strongest fire resistance in the color steel plate series. The rock wool sandwich panel meets the secondary fire protection requirements of the clean workshop, and is an ideal structural decorative panel for the construction of indoor ceilings and movable rooms. The rock wool color steel sandwich panel is refractory to 600 ℃, and the refractory grade reaches Class A.

In the rock wool product market, there are a lot of shoddy products. A large number of slag wools that do not meet the standards of weather resistance, acidity coefficient, tensile strength, slag ball content, hydrophobicity, moisture absorption rate, bulk density, etc. pretend to be qualified rock wool, seriously disrupting the market, and reducing the service life of rock wool and related application products. quality of performance.

The glass wool of the glass wool color steel sandwich panel is made of artificial inorganic fibers with a diameter of less than 6 microns after being melted in a furnace by minerals such as lime and quartz powder, and then drawn by high-speed centrifugation or spraying. It is then made into products by forming equipment.

The main glass wool color steel plates are: glass wool board, glass wool tube, glass wool felt three series. The product has a series of advantages such as low thermal conductivity, small bulk density, stable chemical properties, non-aging and non-flammability. It has good construction performance, easy cutting and processing, no on-site loss, no harmful gas generation, and long-term use performance remains unchanged.