Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Sandwich Panel

PU Sandwich Panel

05Jul, 2022

The polyurethane cold storage board uses lightweight polyurethane as the inner material of the cold storage board. The advantage of polyurethane is that the thermal insulation performance is very good. The exterior of the polyurethane cold storage board is made of color steel plate and stainless steel plate. Electricity improves cooling efficiency.

The cold storage board is made of rigid polyurethane or polyethylene foam insulation sandwich panels, and is molded by high-pressure foaming process at one time. It can be made into various lengths and specifications to meet the different requirements of users.

The panels and walls of the cold storage are all produced by a unified mold. They are connected by internal concave-convex grooves, which are convenient for loading, unloading, and transportation. The installation period is short. The small and medium-sized cold storage can be delivered in 2-5 days. Small.

For the installation specifications of the polyurethane cold storage board of the fresh-keeping warehouse, it is recommended that 10 cm be the optimal thickness of the cold storage board. In addition, some cool warehouses (about 20°C) for storing dry goods and medicinal materials also usually use polyurethane cold storage boards with a thickness of 10 cm.

In addition to the thickness specification of the polyurethane cold storage panel, some freezers/quick freezers will use double-sided stainless steel instead of color steel plates, which can better ensure the thermal insulation performance and prolong the service life of the cold storage.

Purpose:

Food and other industries refrigeration equipment: such as refrigerators, freezers, cold storage, refrigerated trucks, etc., polyurethane rigid foam is the most ideal insulation material for refrigeration equipment.

Features:

1. Rigid polyurethane has low thermal conductivity and good thermal performance. When the density of rigid polyurethane is 35~40kg/m³, the thermal conductivity is only 0.018g~0.023w/(m.k), which is equivalent to about half of EPS, which is the lowest thermal conductivity among all thermal insulation materials.

2. The polyurethane cold storage board has moisture-proof and waterproof performance. The closed cell rate of rigid polyurethane is above 90%, which is a hydrophobic material, which will not increase the thermal conductivity due to moisture absorption, and the wall will not seep water.

3. Polyurethane cold storage panel is fireproof, flame retardant and high temperature resistant. After adding flame retardant, polyurethane is a flame-retardant self-extinguishing material. Its softening point can reach above 250 degrees Celsius, and it will only decompose at higher temperatures. In addition, polyurethane will form ash on the surface of its foam when it burns. This layer of ash helps isolate the foam below and can effectively prevent the spread of fire. Moreover, polyurethane does not generate harmful gases at high temperatures.

4. Due to the excellent thermal insulation properties of the polyurethane panel, the thickness of the outer protective structure of the building can be reduced under the same thermal insulation requirements, thereby increasing the indoor usable area.

5. The porosity structure of the polyurethane sandwich panel is stable, and it is basically a closed-cell structure, which not only has excellent thermal insulation performance, but also has good freeze-thaw resistance and sound absorption. The average lifespan of the rigid foam polyurethane insulation structure can reach more than 30 years under normal use and maintenance conditions. It can be achieved that the unit price of the raw foam material is higher than that of other traditional insulation materials under normal use conditions during the life of the structure, dry, wet or galvanic corrosion, and due to insects, fungi or algae. But the increased costs will be offset by substantial reductions in heating and cooling bills.

6. There are many specifications and varieties, the range of bulk density: (40-60kg/m³); the range of length: (0.5m-4m); the range of width: (0.5m-1.2m); the range of thickness: (20mm-200mm).

7. The cutting precision is high, and the thickness error is ±0.5mm, thus ensuring the flatness of the surface of the finished product.

8. It is convenient for quality inspection. Since the surrounding skin is removed during the cutting process, the quality of the board is clear at a glance, which ensures the thermal insulation effect of the finished product.

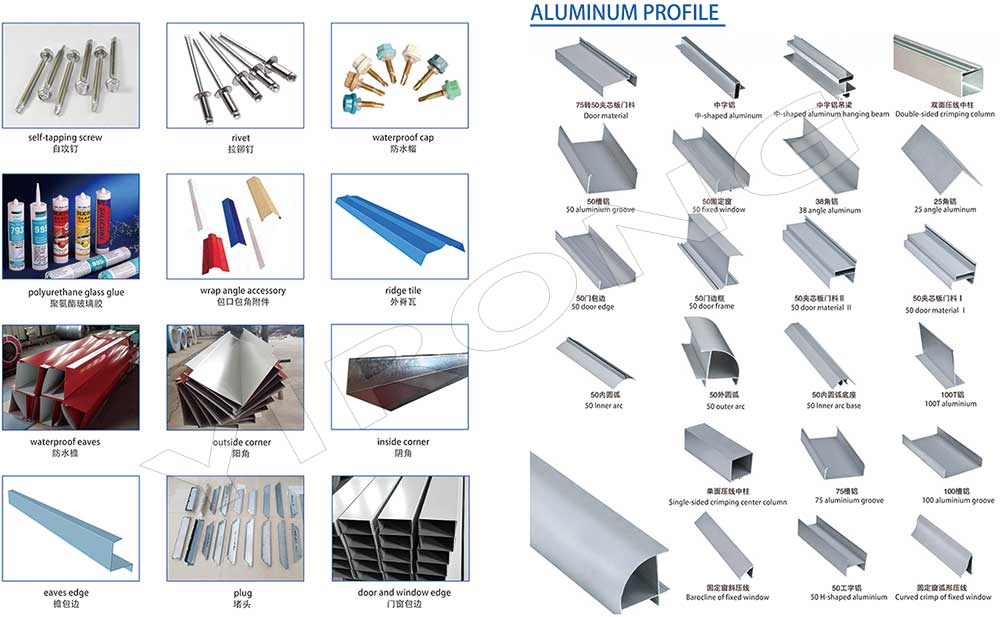

If you purchase metal sandwich panels from Yirong Company, we will also provide some accessory products, including self tapping nails, rivets, waterproof caps, polyurethane glass glue, mouth and corner accessories, outer ridge tiles, waterproof eaves, external and internal corners, eaves edging, plugs, door and window edging, purified aluminum profiles, etc.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged. And all the structure components, panels, bolts and sorts of accessories will be well packed with standard package and it is suitable for ocean transport.

1. Inspection: 50% inline inspection and 100% full final inspection, make sure all output w/o any mistake.

2. Packing: Per customer's requirements or per product sizes, full protection packing.

3. Shipping: Per customer's requirements or per container sizes.

4. Unloading: We package it as a whole and can be easily pulled out at once with a forklift, which is very convenient.