Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Sandwich Panel

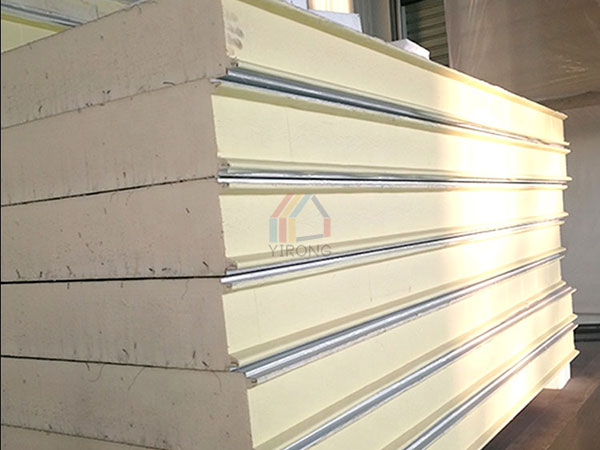

PU Sandwich Panel

01Jun, 2022

PU composite wall panels are used in large industrial plants, warehouses, stadiums, supermarkets, hospitals, cold storage, mobile homes, building plus floors, clean workshops and places where insulation and fire protection are required.

The sandwich panel has beautiful appearance, bright color and good overall effect. It integrates load-bearing, heat preservation, fireproof and waterproof, and does not require secondary decoration. It is a kind of versatile, especially in temporary facilities such as offices and warehouses for construction sites, the wall, etc., more embodies the civilized construction of modern construction sites, especially in terms of rapid installation and use, there are obvious advantages in the detachable and recyclable index of materials that can be installed, and the temporary facilities cost of construction sites is greatly reduced.

Effective coverage width: 1m

Sheet thickness: 0.4-0.8mm

Core thickness: 50/75/100/120/150/200mm

Usage: PU composite wall panel is a bimetallic surface, single metal surface, and non-metallic surface composite sheet with polyurethane rigid foam as the thermal insulation layer.

Characteristics of pu wall panel:

A. Low thermal conductivity Polyurethane sandwich panel composite board has low thermal conductivity and good thermal insulation performance, and is the best thermal insulation material.pu wall panel

B. Beautiful shape and easy installation

C. Polyurethane sandwich panel has good fire resistance

D. Polyurethane sandwich panel is non-toxic and tasteless

E.Wide operating temperature range

F. Waterproof and moisture proof

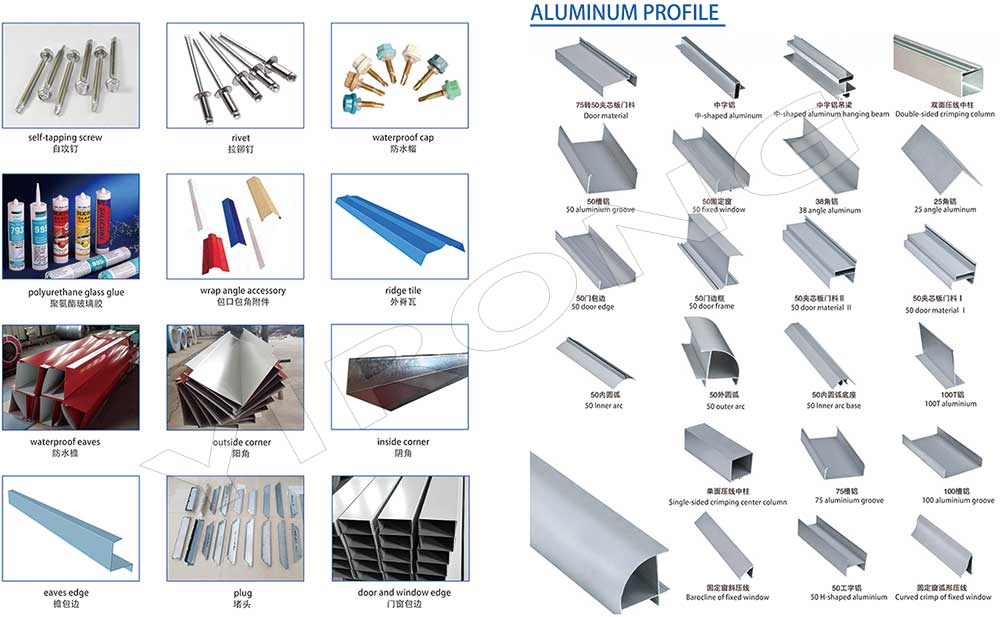

If you purchase metal sandwich panels from Yirong Company, we will also provide some accessory products, including self tapping nails, rivets, waterproof caps, polyurethane glass glue, mouth and corner accessories, outer ridge tiles, waterproof eaves, external and internal corners, eaves edging, plugs, door and window edging, purified aluminum profiles, etc.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged. And all the structure components, panels, bolts and sorts of accessories will be well packed with standard package and it is suitable for ocean transport.

1. Inspection: 50% inline inspection and 100% full final inspection, make sure all output w/o any mistake.

2. Packing: Per customer's requirements or per product sizes, full protection packing.

3. Shipping: Per customer's requirements or per container sizes.

4. Unloading: We package it as a whole and can be easily pulled out at once with a forklift, which is very convenient.