Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Sandwich Panel

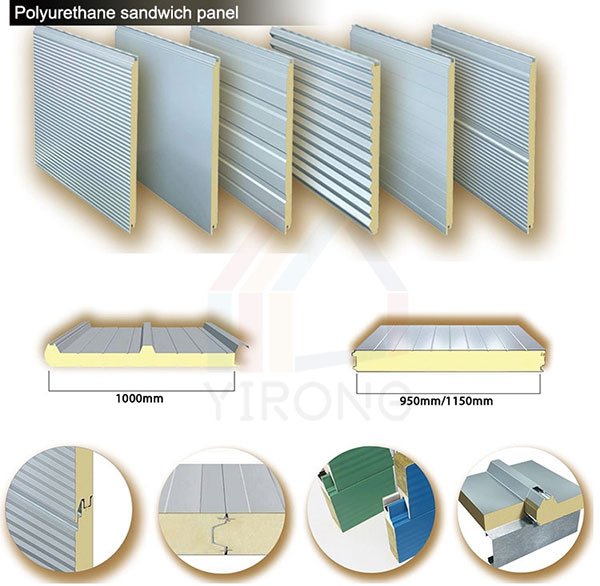

PU Sandwich Panel

01Jul, 2022

The polyurethane partition board is composed of upper and lower color steel plates and intermediate foamed polyurethane, which has strong stability. Polyurethane is a new type of building material with the advantages of easy installation, improved construction efficiency and shortened construction period. Polyurethane sandwich panels can replace wooden boards, and the construction is pollution-free and saves energy.

The polyurethane partition wall panel adopts a fully enclosed design, and a sealing strip is set between the top panels to ensure the airtightness of the roof. The structural design of the pu sandwich panel is reasonable, and the hidden screw installation structure completely solves the problem of roof leakage. The polyurethane roof panels are connected by dark nails, and the panels are closely overlapped. The unique waterproof groove design can effectively prevent the infiltration of rainwater and avoid the phenomenon of cold bridge.

Product advantages:

1. The concave-convex groove structure improves the insulation and air-tightness of the joints of the plates, and is specially designed for cold rooms and cold storages.

2. The polyurethane partition board is uniform and stable, with good heat insulation and waterproof performance.

3. Light weight, beautiful appearance, effectively solve the temperature difference in refrigeration industry.

4. Rigid polyurethane has low thermal conductivity and good thermal performance. When the density of rigid polyurethane is 35~40kg/m3, the thermal conductivity is only 0.018g~0.023w/(m.k), which is equivalent to about half of EPS, which is the lowest thermal conductivity among all thermal insulation materials at present.

5. Due to the excellent thermal insulation performance of polyurethane panel, under the same thermal insulation requirements, the thickness of the outer protective structure of the building can be reduced, thereby increasing the indoor usable area.

6. Strong anti-deformation ability, not easy to crack, stable and safe finish.

Application areas:

Food quick-freezing processing and refrigeration, food processing plants, dairy product storage, biological and pharmaceutical products, indoor assembled cold storage, cold chain transportation vehicle cold storage.

Energy saving and heat preservation

The closed cell rate of the core material is greater than or equal to 97%, and the thermal insulation performance is excellent.

Fire retardant

The product has passed the inspection, and the combustion level has reached the B1 level standard.

Airtight soundproofing

It has good sound absorption and can reduce the sound caused by the impact of rain and hail.

Green environmental protection

Formaldehyde-free, free from microbial invasion, and recyclable.

Beautiful and economical

Various surface forms and rich colors; reduce material loss, save construction time and engineering costs.

Fast construction

Polyurethane panels are produced in a highly controlled and constant temperature environment in the factory, with stable quality and fast construction, and have been used for more than 35 years.