Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

With the acceleration of global industrialization and the frequent occurrence of extreme climates, high-temperature resistant PUF panels have become popular materials in the fields of construction, industrial manufacturing, cold chain logistics, etc. due to their unique comprehensive performance. This article will start from the perspective of the global market, deeply explore the technical characteristics, competitive advantages, application fields and price trends of PUF sandwich panels, and analyze how Yirong, a well-known sandwich panel supplier in China, empowers the development of the industry.

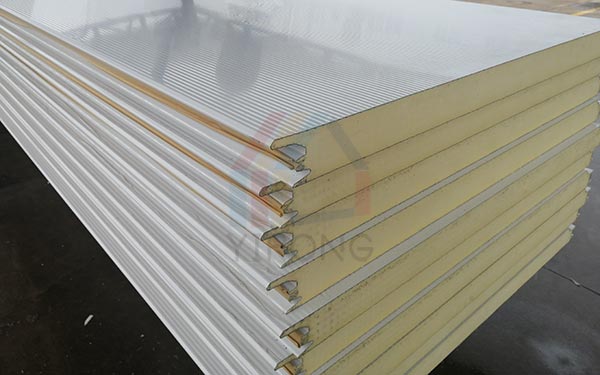

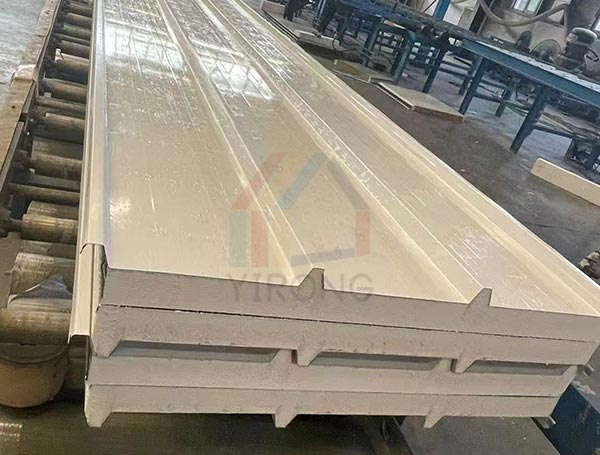

PUF panel (polyurethane foam sandwich panel) is a new composite material with polyurethane (PU) as the core material and two-sided composite metal sheets (such as color-coated steel plates and aluminum plates). Its core advantage is that after special formula and process treatment, it can achieve a temperature resistance range of -50℃ to 150℃. Some high-end products can even withstand high temperatures of 200℃ for a short period of time, while also having excellent fireproof, sound insulation and corrosion resistance.

1. Green building and energy-saving policies

Policies such as the EU Energy Performance of Buildings Directive (EPBD) and China's "dual carbon" goals have driven the construction industry to transform to high-efficiency insulation materials. The thermal conductivity of PUF panel is as low as 0.022 W/(m·K), which is 30% more energy-efficient than traditional rock wool board, making it the first choice for scenes such as factories and cold storage.

2. Explosive growth of cold chain logistics

According to Grand View Research data, the global cold chain market size will reach US$326 billion in 2023, with an annual compound growth rate of more than 12%. High-temperature resistant PUF board is highly favored for its temperature control stability in vaccine transportation and fresh food storage.

3. Industrial high-temperature environment demand

Chemical, food processing, lithium battery manufacturing and other fields have strict requirements on the heat resistance of equipment protection materials, which promotes PUF panel to replace traditional galvanized sheet.

1. Excellent thermal stability

By adding flame retardants and ceramic fiber modification technology, PUF board is not easy to deform and carbonize at high temperature, and its service life is extended to more than 15 years.

2. Class A fireproof certification

Modified with inorganic gelling materials, the product fireproof level can reach GB8624 A1 level (non-flammable), meeting the needs of high-risk places such as airports and hospitals.

3. Modular installation and lightweight

The weight is only 1/10 of the concrete board. With the pre-installed buckle design, the construction efficiency is increased by 50%, which greatly reduces labor and transportation costs.

4. Environmental protection throughout the life cycle

The recyclability rate is 90%, and the CO₂ emissions during the production process are 40% lower than that of rock wool, which is in line with the development trend of ESG.

| Area | Mainstream price range (USD/㎡) | Core influencing factors |

| China | $8-15 | Large scale production+policy subsidies |

| Europe | $20-35 | Strict environmental standards+short local supply chain |

| North America | $20-35 | Strong demand for high-end customization |

| Southeast Asia | $10-18 | Low labor cost+high dependence on imports |

Note: The price is significantly affected by crude oil price fluctuations (affecting polyurethane raw materials), tariff policies and transportation costs. Data from Q2 2024 showed that due to the Red Sea shipping crisis, freight rates on the Asia-Europe route rose by 25%, resulting in an increase of about 12% in the price of PUF boards in the European market.

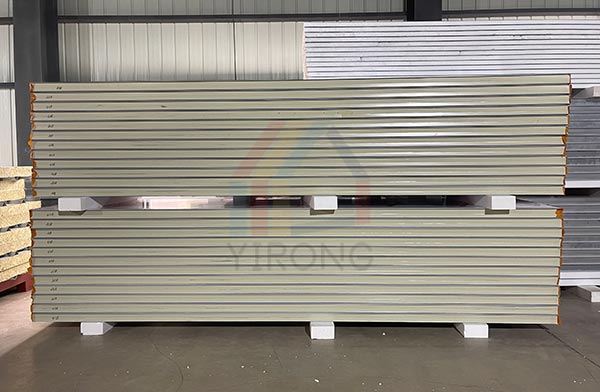

As China's leading sandwich panel manufacturer, Yirong sandwich panel supplier helps customers reduce costs and increase efficiency through the following core advantages:

1. Full industry chain intelligent manufacturing capabilities

Multiple fully automatic continuous production lines with a daily production capacity of 10,000 square meters.

2. Customized technical services

Provide customized formulas from -70℃ ultra-low temperature to 200℃ wide temperature range. Passed international certifications such as UL94 and EN13501, and supports EU CE and North American ASTM standard exports.

With the advancement of new infrastructure such as 5G base stations and hydrogen energy facilities, high-temperature resistant PUF panels will usher in greater demand in the fields of electromagnetic shielding and chemical corrosion resistance. According to MarketsandMarkets, the global sandwich panel market size will exceed US$19 billion in 2025, of which the Asia-Pacific region accounts for more than 40%. Yirong sandwich panels are expected to take the lead in this growth wave through continuous investment.