Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

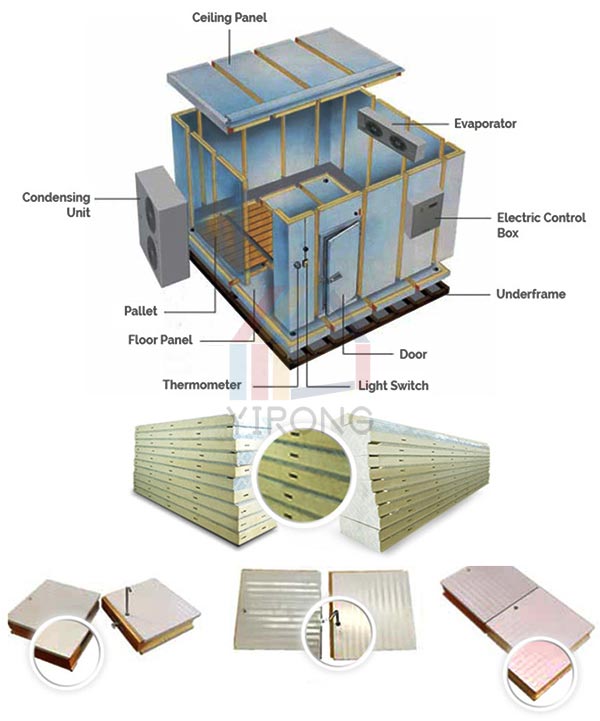

In modern industry and cold chain logistics, cold rooms are the core facilities of temperature-controlled environments, and the choice of construction materials is directly related to energy efficiency and operating costs. The cold room panels (also known as the cold room insulation sandwich panel) has become the preferred material for cold storage construction due to its excellent insulation performance and structural strength. This article will deeply analyze the definition, working principle and core advantages of the cold storage panel, and recommend a high-quality supplier-Yirong sandwich panel to help you efficiently build a high-performance cold room.

The cold room panel is a composite panel designed for low-temperature environments and is a type of insulation sandwich panel. Its structure is usually made of double-sided metal panels (such as color steel plates, stainless steel plates) and high-density insulation core materials (such as polyurethane, rock wool, polystyrene) in the middle through a high-pressure bonding process. This "sandwich" structure gives the cold room board multiple characteristics such as light weight, high strength, heat insulation, and moisture resistance, and is widely used in cold room scenes such as cold storage, food processing workshops, and pharmaceutical warehousing.

The core function of the cold room board is to isolate the heat transfer between the inside and outside and maintain a constant temperature environment inside the cold room. Its working principle is based on the following three points:

1. High-efficiency insulation layer: The closed-cell structure of the core material greatly reduces the thermal conductivity and reduces the loss of cold. For example, the thermal conductivity of the polyurethane core material is as low as 0.022 W/(m·K), and the insulation performance is far superior to traditional materials.

2. Sealed moisture-proof design: The seamless bonding of the metal panel and the core material can block the penetration of water vapor and avoid condensation inside the cold room or aging of the insulation layer.

3. Structural stability: The cold storage panel has both lightweight and high load-bearing capacity, can adapt to the frequent temperature changes in the cold room, and will not deform after long-term use.

1. Cold chain logistics: cold storage walls, roofs and partitions.

2. Food processing: temperature control environment construction of meat and dairy processing workshops.

3. Pharmaceutical warehousing: insulation enclosure system for vaccine and drug storage cold rooms.

4. Industrial low-temperature workshop: special production environment of chemical and electronics industries.

Among many suppliers of insulation sandwich panels, Yirong Sandwich Panel stands out with its technical strength and quality assurance, becoming a trusted brand in the industry:

Product advantages:

Provide a variety of core cold room panels such as polyurethane (PU), rock wool (RW), glass wool (GW), etc. to meet different temperature requirements (-50℃ to +100℃).

The panels can be galvanized, stainless steel, antibacterial coating, etc., suitable for high hygiene standard scenes such as food and medicine.

Customized service:

Support non-standard size customization, provide fast production and installation guidance, and shorten the project cycle.

Quality certification:

Passed ISO 9001 quality management system certification, the product meets fire protection and environmental protection standards (such as Class A flame retardant).

1. Energy saving and consumption reduction: The thermal insulation performance is improved by 30%, significantly reducing the operating cost of the cold room.

2. Strong durability: Corrosion-resistant metal panel + stable core material, with a service life of more than 20 years.

3. One-stop service: from design consultation to installation and after-sales, full technical support.

As the core material for cold room construction, the performance of cold room panels directly determines the temperature control effect and energy efficiency. Choosing Yirong sandwich panel suppliers can not only obtain high-quality insulation sandwich panels, but also enjoy professional customization services, providing reliable guarantees for your cold storage projects. Contact Yirong sandwich panel suppliers now to get personalized cold room solutions!