Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

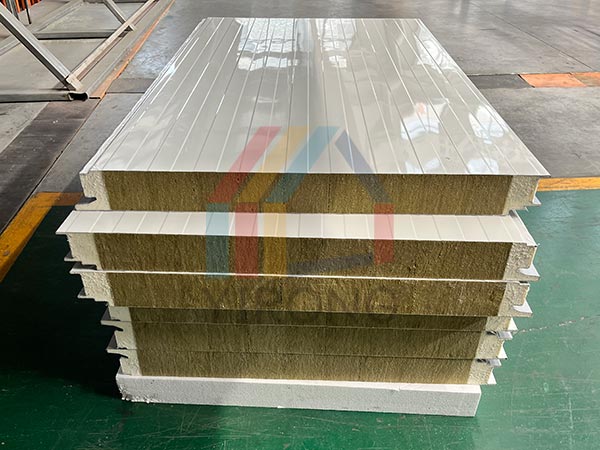

Polyurethane edge-sealed rock wool sandwich panel is a new type of building material, which is widely used in industrial plants, cold storage, commercial buildings and other fields. Due to its excellent thermal insulation, sound insulation and fire resistance properties, more and more construction projects are beginning to use this material. However, among the many brands and specifications, how to choose the appropriate polyurethane edge-sealed rock wool sandwich panel is a problem that needs serious consideration. This article will provide you with guidance on your choice from many aspects.

1. Understand the basic characteristics of polyurethane edge-sealed rock wool sandwich panels

Before choosing, you must first understand the basic characteristics of polyurethane edge-sealed rock wool sandwich panels:

2. Clarify usage scenarios

To choose a suitable polyurethane edge-sealed rock wool sandwich panel, you must first clarify its usage scenario. Different application scenarios have different requirements for materials:

3. Consider board thickness

The thickness of the polyurethane edge-sealed rock wool sandwich panel directly affects its thermal insulation performance. Generally speaking, the thicker the board, the better the insulation effect. When selecting, the thickness should be determined based on local climate conditions, building type and usage requirements:

4. Check the technical parameters of the material

When choosing polyurethane edge-sealed rock wool sandwich panels, you need to pay attention to the following technical parameters:

5. Reputation of brand and manufacturer

It is important to choose a well-known brand and a reputable manufacturer. Well-known brands usually have more complete production processes and quality control systems. When choosing, consider:

6. Costs and budgets

The price of polyurethane edge-sealed rock wool sandwich panels varies depending on the brand, specifications and market supply and demand. When choosing, you need to reasonably control costs on the premise of meeting quality:

7. After-sales service and technical support

High-quality after-sales service and technical support are factors that cannot be ignored when choosing polyurethane edge sealing rock wool sandwich panels. Good after-sales service can help you solve problems during use and ensure the long-term stability of the product:

8. Environmental friendliness

As environmental awareness increases, choosing environmentally friendly materials has become increasingly important. During the production and use of polyurethane edge-sealed rock wool sandwich panels, whether they comply with environmental standards will directly affect the sustainability of the building. When choosing, you can pay attention to the following points:

Conclusion

Choosing a suitable polyurethane edge-sealed rock wool sandwich panel is a systematic project that requires comprehensive consideration of multiple factors, including usage scenarios, panel thickness, technical parameters, brand reputation, cost, after-sales service and environmental protection, etc. Through comprehensive analysis and comparison, you will be able to find the sandwich panel that best suits your project needs, providing a strong guarantee for the safety, comfort and economy of the building.