Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

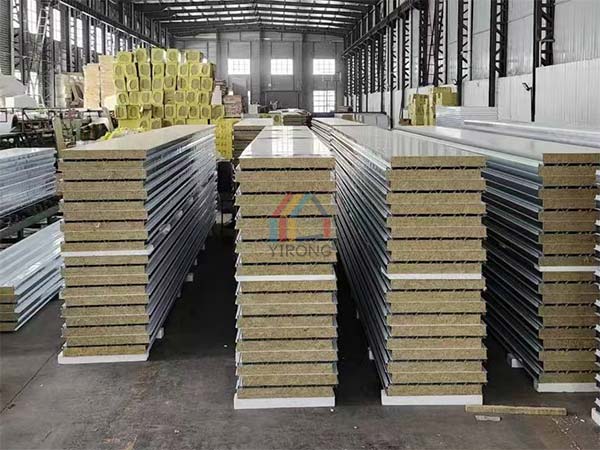

As a high-quality thermal insulation material, rock wool roof panels have been widely used in the construction field. Its excellent thermal insulation and fireproof properties make rock wool roof panels the preferred material in many construction projects. Below, let's take a closer look at the installation steps and precautions of rock wool roof panels.

1. Construction preparation

Before installing rock wool roof panels, detailed construction preparations must be made first. This includes checking the construction drawings, understanding the construction environment, and preparing necessary construction tools and equipment, such as cutting machines, electric drills, screwdrivers, etc. At the same time, ensure the safety and health of construction workers and wear appropriate personal protective equipment, such as gloves, masks, and goggles. In addition, the quality of the rock wool board needs to be checked to ensure that it meets relevant standards and design requirements.

2. Base treatment

Base treatment is an important step in the installation of rock wool roof panels. Before installation, the base should be cleaned, dried, and leveled to ensure that the base is free of defects such as oil, dust, and cracks. For uneven parts, repair and leveling should be carried out to ensure the flatness and stability of the rock wool board installation. The cleanliness and dryness of the base layer directly affect the pasting effect and thermal insulation performance of the rock wool board, so this step cannot be ignored.

3. Rock wool board cutting

Cut the rock wool board into the required size according to actual needs. During the cutting process, use professional cutting tools to ensure accurate size and neat edges. Avoid using inappropriate tools to damage the rock wool board. At the same time, pay attention to the dust generated during cutting and take appropriate protective measures to protect the health of construction workers.

4. Paste the rock wool board

Before pasting, apply a special adhesive on the base layer to ensure that the adhesive is uniform and appropriate. Then, paste the rock wool board according to the predetermined position, paying attention to maintaining the flatness and verticality of the rock wool board. During the pasting process, avoid hollowing and warping of the rock wool board to ensure that the pasting is firm and seamless. At the same time, pay attention to the gaps between the rock wool boards to avoid problems such as air leakage and water leakage.

5. Installation of fixings

In order to ensure the stability and safety of the rock wool roof board, fixings need to be installed. The installation position and number of fixings should be determined according to the design drawings and construction requirements. When installing the fixings, pay attention to the material, specifications and models of the fixings to ensure that they meet the relevant standards and requirements. At the same time, ensure that the fixings are installed firmly and without looseness.

6. Joint treatment

The joint treatment between the rock wool roof panels are also an important part of the installation process. At the joints, apply special sealing materials to ensure that the joints are tightly sealed and leak-free. At the same time, pay attention to the flatness and aesthetics of the joints to avoid obvious unevenness or color differences.

7. Protection layer construction

After the installation of the rock wool roof panel is completed, the protection layer needs to be constructed. The main function of the protection layer is to protect the rock wool board from erosion and damage from the external environment and extend its service life. The construction of the protective layer should be carried out according to the design drawings and construction requirements to ensure that the material, thickness and construction quality of the protective layer meet the relevant standards and requirements.

8. Construction acceptance

After the installation of the rock wool roof panel is completed, the construction acceptance should be carried out. During the acceptance, the installation quality of the rock wool board, the installation of the fixings, the joint treatment, etc. should be checked to ensure that all indicators meet the design requirements and relevant standards. At the same time, fire safety inspections and thermal insulation performance tests are also required to ensure the use effect and safety performance of rock wool roof panels.

The installation of rock wool roof panels needs to follow strict steps and precautions to ensure construction quality and use effect. Through scientific construction methods and fine construction operations, we can give full play to the thermal insulation performance of rock wool roof panels and contribute to energy saving and consumption reduction and comfortable environment of construction projects.