Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

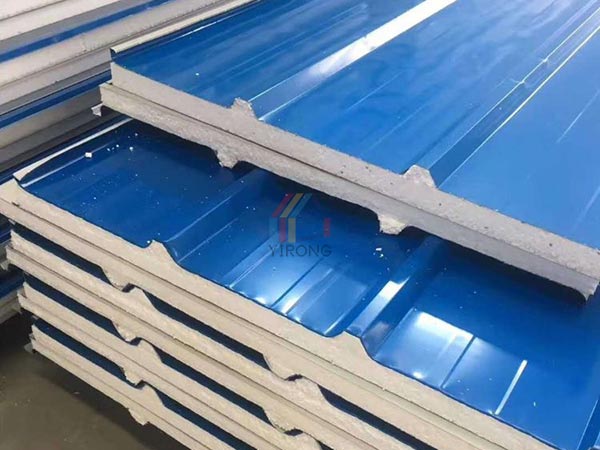

Color steel sandwich panels, as a lightweight, high-strength, and well insulated building material, are widely used in the roofs and walls of industrial factories, warehouses, exhibition halls, and other buildings. The installation process requires certain skills and experience. Below, we will provide a detailed introduction to the installation steps and precautions for the color steel sandwich panel roof.

Preparation before installation

Material inspection: Ensure that the quality of the color steel sandwich panel, connectors, sealant and other materials is qualified and the quantity is complete.

Tool preparation: Prepare necessary tools such as an electric drill, screwdriver, cutting machine, tape measure, level, ink bucket, etc.

Safety protection: Construction personnel must wear protective equipment such as helmets, safety shoes, and gloves to ensure construction safety.

Installation steps

Measurement and marking: Firstly, according to the architectural design drawings, mark the installation position of the color steel sandwich panel on the roof with an ink bucket and a level. Ensure that each board is arranged neatly and that the gaps between boards are even.

Fixed support structure: Install steel frames or other support structures according to design requirements to ensure stability and reliability. The levelness and verticality of the supporting structure should meet the regulatory requirements.

Installation of color steel sandwich panel: Place the color steel sandwich panel in the marked position and fix it to the support structure with special connectors or screws. Pay attention to maintaining the flatness and verticality of the board.

Joint treatment: The joints between the color steel sandwich panels should be sealed with special sealant to ensure waterproof and insulation performance.

Install ridge and gutter: Install ridge and gutter according to design requirements to ensure smooth drainage.

Inspection and adjustment: After installation, conduct a comprehensive inspection of the entire roof to ensure that all connection parts are firm and reliable, and there is no leakage. If necessary, make appropriate adjustments.

Matters needing attention

Material selection: Choose high-quality and stable color steel sandwich panels and other supporting materials to ensure the quality of the project.

Construction sequence: Install in the order of difficulty first, easy first, and high then low to ensure construction efficiency and project quality.

Construction environment: Avoid construction in adverse weather or extreme weather conditions such as high and low temperatures to avoid affecting material performance and construction quality.

Safety protection: During the construction process, strict adherence to safety operating procedures is required to ensure the personal safety of construction personnel.

The installation of color steel sandwich panel roof is a complex and meticulous process that requires construction personnel to have professional skills and experience. Through reasonable material selection, meticulous construction planning, and strict construction management, the installation quality and usage effect of color steel sandwich panel roofs can be ensured.