Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Sandwich Panel

Purification Board

28Jun, 2022

The manual purification board is all hand-made, and can be customized and assembled according to the customer's engineering requirements. The manual purification board can not only greatly reduce the cost of the basic engineering and structural engineering of the building, but also can be disassembled and assembled many times. The construction and installation are convenient and fast, and the comprehensive benefit is very significant.

Rock wool, polyurethane foam, silica rock, glass wool, paper honeycomb, aluminum honeycomb, glass magnesium board, etc. can be used to purify the core of the board manually.

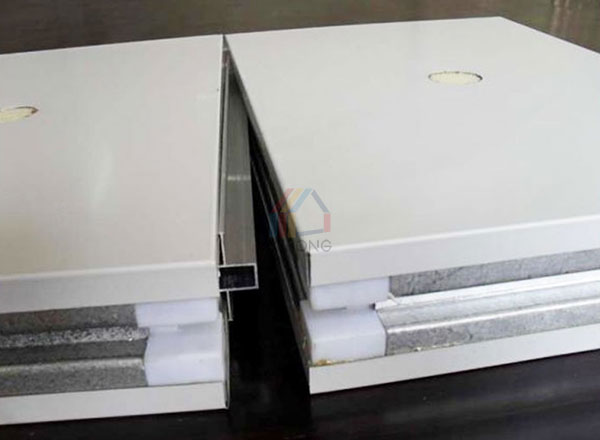

Weld-free lap joint

There are three types of lap joints for manual purification boards: "Lap joint of central aluminum partition wall", "Lap joint of wafer-type detachable partition wall" and "Lap joint of wide-slot partition wall", while the tongue and groove board adopts the joint method of sub-mother joint.

The installation is adjustable, convenient and quick

The clean board is used to separate the space, and it is only necessary to separate the space by a simple plane, discharge the processing size of the board, and process the board according to the layout size.

Good sealing effect and light weight

The product has good sealing effect and high cleanliness. And light weight and high strength.

Accurate construction and simple acceptance

The connection between the upper opening of the manual purification board and the top board is a self-tapping screw connection, and the flatness and verticality of the board can be adjusted at any time to ensure accurate and fast construction. Installation and acceptance can be carried out at the same time.

Beautiful, hygienic and economical

The purification board is beautiful in appearance, clean and hygienic, its performance meets environmental protection requirements, and has the characteristics of reusability, which is economical and affordable.

Product features of purification board:

1. The surface is smooth and the appearance quality is superior.

2. Easy installation, high efficiency, and low cost compared to manual production.

3. Rock wool core material is rock, blast furnace iron slag, etc. are melted into filaments at high temperature, and then solidified and formed.

4. It has good sound absorption, sound insulation performance and good fire resistance. Tests have shown that it has fire resistance at 650 ° C, and the fire resistance grade reaches Class A.

5. The interface is tight and the heat is not easily conducted. When the temperature in the furnace is 180 °C, the temperature of the outer plate is lower than the normal temperature +5 °C.

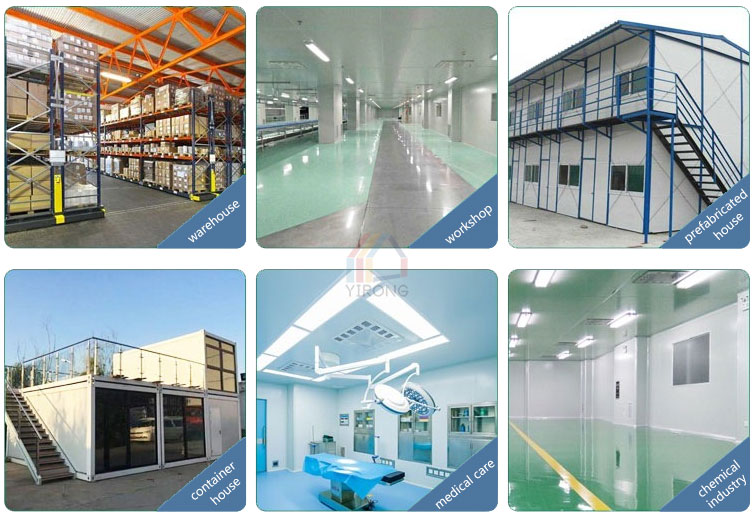

Application scenarios:

The purification board has unique dustproof, antistatic and antibacterial effects. Widely used in purification engineering fields, such as electronics, pharmaceuticals, food, biology, aerospace, precision instrument manufacturing and scientific research.

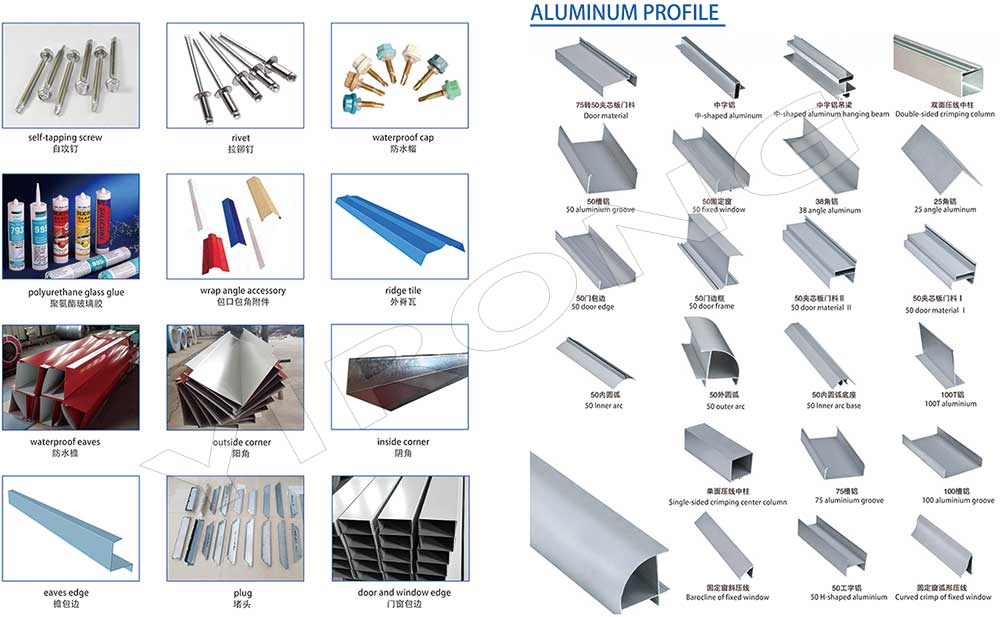

If you purchase metal sandwich panels from Yirong Company, we will also provide some accessory products, including self tapping nails, rivets, waterproof caps, polyurethane glass glue, mouth and corner accessories, outer ridge tiles, waterproof eaves, external and internal corners, eaves edging, plugs, door and window edging, purified aluminum profiles, etc.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged. And all the structure components, panels, bolts and sorts of accessories will be well packed with standard package and it is suitable for ocean transport.

1. Inspection: 50% inline inspection and 100% full final inspection, make sure all output w/o any mistake.

2. Packing: Per customer's requirements or per product sizes, full protection packing.

3. Shipping: Per customer's requirements or per container sizes.

4. Unloading: We package it as a whole and can be easily pulled out at once with a forklift, which is very convenient.