Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

In the construction and decoration market, rock wool sandwich panels and silica rock panels are two common materials. They each have unique advantages, but there are also some differences. This article will conduct a detailed comparison of these two materials to help users better understand their characteristics and applications.

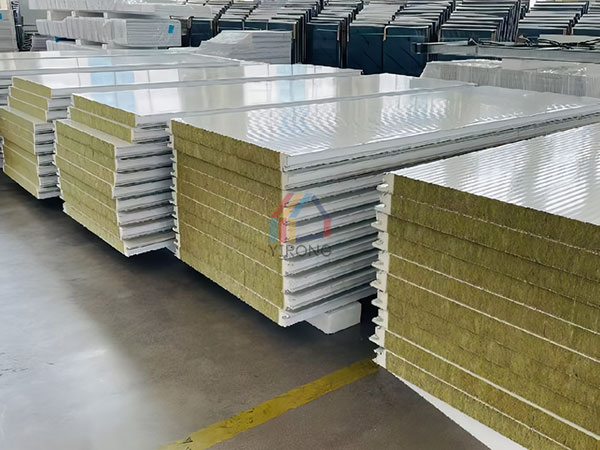

Rock wool sandwich panel:

Rock wool sandwich panel is a building material composed of rock wool, organic or inorganic binders and surface materials. Its main features are light weight, good fire resistance, good sound insulation effect, and good thermal insulation performance. Rock wool sandwich panels are mainly used in building exterior walls, partitions, roof insulation and other fields.

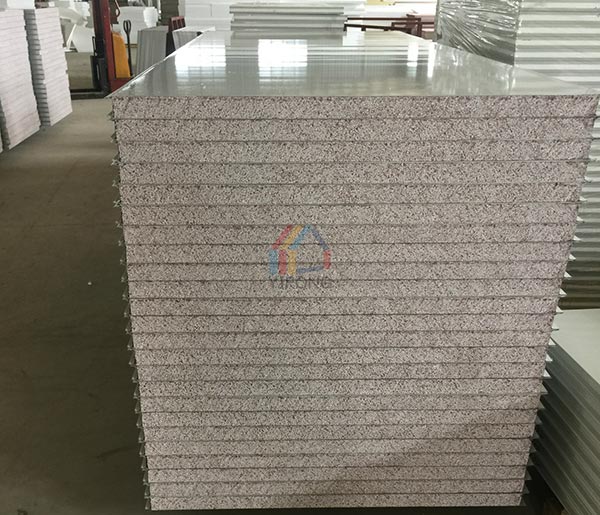

Silica rock board:

Silica rock board is an inorganic material made of siliceous materials (such as diatomite, quartz, etc.) as the main raw material and sintered at high temperature. Silica rock board has the advantages of light weight, high strength, good fire resistance, good durability, etc. It does not contain any harmful substances and is a green and environmentally friendly building material. Silica rock panels are mainly used in interior decoration, exterior walls, furniture and other fields.

Thermal insulation performance:

Both rock wool sandwich panels and silica rock panels have good thermal insulation properties, but silica rock panels have a lower thermal conductivity, so their thermal insulation performance is slightly better than rock wool sandwich panels.

Fire performance:

Both materials have good fire resistance, but the fire resistance level of silica rock panels is higher and can reach Class A non-combustible level, while the fire resistance of rock wool sandwich panels is generally Class B. Therefore, silica rock panels are more suitable in situations with higher fire protection requirements.

Sound insulation performance:

Because the rock wool sandwich panel contains a large number of voids inside, it has good sound insulation effect. The sound insulation performance of silica rock panels is relatively poor, but it can still meet the needs of general indoor sound insulation.

Environmental performance:

Silica rock panels do not use any chemical additives during the production process and do not contain harmful substances such as formaldehyde. They are a green and environmentally friendly material. Although rock wool sandwich panels are also more environmentally friendly, there may be some environmental pollution problems during the production process.

Rock wool sandwich panel:

Due to its good thermal insulation, fire protection and sound insulation properties, rock wool sandwich panels are widely used in building exterior walls, partitions, roof insulation and other fields. It is especially widely used in situations where insulation and fire protection properties are required, such as hospitals, schools, hotels and other buildings.

Silica rock panel:

Silica rock panels are mainly used in interior decoration, exterior walls and furniture. Due to its light weight, high strength, good fire resistance, good durability and other advantages, and does not contain any harmful substances, it is especially suitable for use in places with high environmental requirements, such as interior walls and walls of office buildings, residences, kindergartens and other buildings. Furniture making.

To sum up, rock wool sandwich panels and silica rock panels each have their own unique advantages and applicable scenarios. In practical applications, appropriate materials should be selected according to specific needs and occasions. If you need materials with better insulation and fire resistance, you can choose rock wool sandwich panels; if you have higher environmental requirements and are mainly used for interior decoration and furniture production, silica rock panels are a better choice.