Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Sandwich Panel

Rock Wool Sandwich Panel

29Jun, 2022

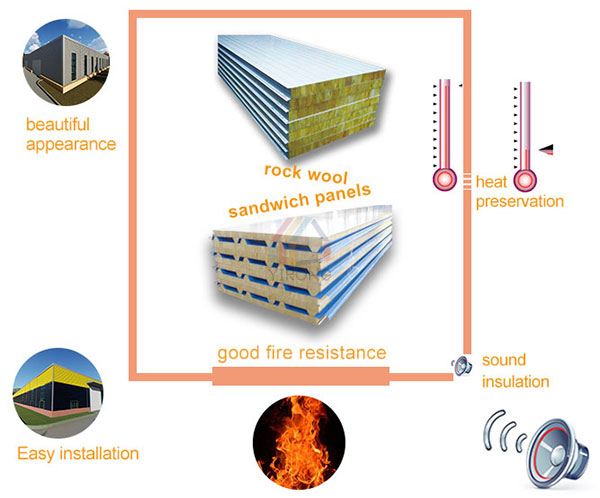

Rock wool sound-absorbing panel is what we usually call sound-absorbing and hydrophobic rock wool panel. It is a mineral fiber product. Rock wool sound-absorbing panel is made of natural rock as raw material, which is melted at high temperature, added with a small amount of binder, spun into fiber by high-speed centrifugation and processed. It is a special board that can be waterproof, sound-absorbing and noise reduction after collection, pendulum and solidification.

Rock wool panel, also known as rock wool insulation decorative board, takes basalt as the main raw material. Rock wool sandwich panel is an artificial inorganic fiber processed by melting. It has the characteristics of light weight, low thermal conductivity, heat absorption and non combustion. Rock wool is an ideal sound insulation material. A large number of slender fibers form a porous connection structure, which determines that rock wool is an excellent noise reduction and sound absorption material.

| Density: 60-200kg/m³ | Density tolerance: ±5 |

| Fiber Average: 4-7 | Volume water absorption: ≤4 |

| Absorption rate: ≤1.0 | Water repellency rate: ≥98 |

| Thermal load shrinkage temperature: ≥650 | Organic content: ≤4% |

| Compressive strength: ≥80 | Peel strength: ≥14 |

| Incombustibility: A1 | Thermal conductivity (70℃): ≤0.041 |

| Acidity coefficient: ≥1.8 | Binder content: ≤3.0 |

Performance of rock wool sound-absorbing board

Rock wool is an inorganic thermal insulation material. It is made of iron slag as the main raw material, which is melted and cooled by high-pressure steam injection. It has the advantages of light weight, low thermal conductivity, good elasticity, non combustion, non decay, and chemical stability. It also has excellent sound insulation performance.

Characteristics of sound absorption panel

1. Superior sound absorption effect can effectively control and adjust the reverberation time of thespace and reduce noise.

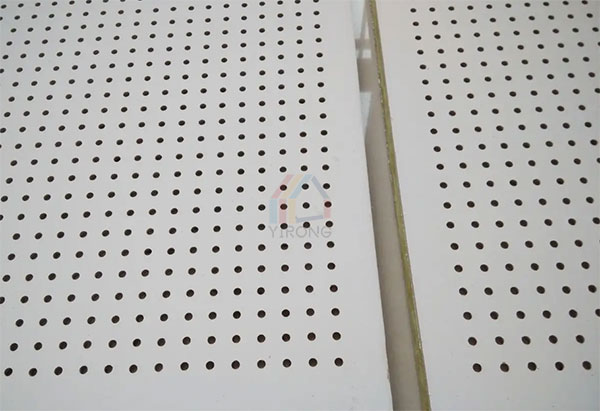

2. The inner panel is firmly bonded with a non-woven fabric backing.3.Aperture: 3-6mm.

4. Opening rate: 78%.

5. The core material is made of glass wool and rock wool for heat insulation and excellent fire pre-vention effect.

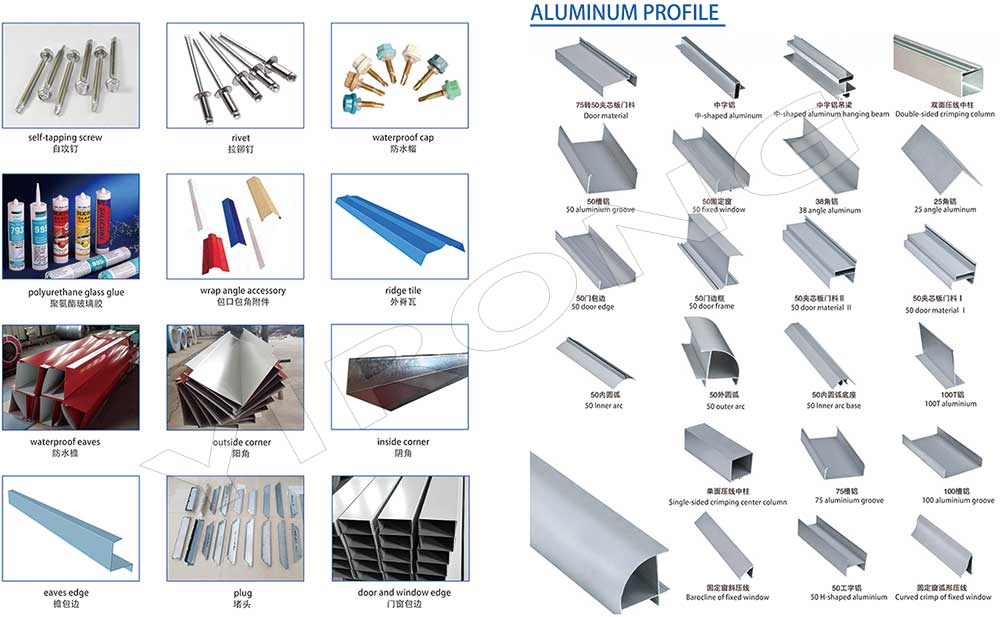

If you purchase metal sandwich panels from Yirong Company, we will also provide some accessory products, including self tapping nails, rivets, waterproof caps, polyurethane glass glue, mouth and corner accessories, outer ridge tiles, waterproof eaves, external and internal corners, eaves edging, plugs, door and window edging, purified aluminum profiles, etc.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged. And all the structure components, panels, bolts and sorts of accessories will be well packed with standard package and it is suitable for ocean transport.

1. Inspection: 50% inline inspection and 100% full final inspection, make sure all output w/o any mistake.

2. Packing: Per customer's requirements or per product sizes, full protection packing.

3. Shipping: Per customer's requirements or per container sizes.

4. Unloading: We package it as a whole and can be easily pulled out at once with a forklift, which is very convenient.