Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

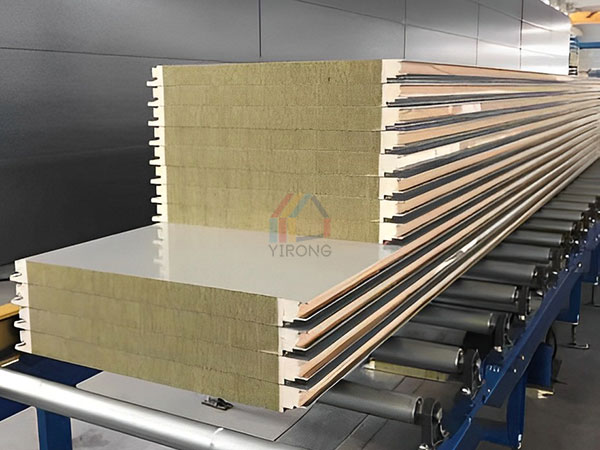

Rock wool sandwich panel is a common building material with good thermal insulation properties. However, due to its poor flame retardancy, it is easy to cause fires, so it is necessary to pay attention to its fire rating when using it.

The fire rating of rock wool sandwich panel is calculated according to national standards. National standards have strict requirements on the fire performance of building materials, including the fire rating classification of different materials. The fire rating of rock wool sandwich panels mainly includes three grades: A, B, and C.

Class A is the highest fire rating and the highest requirement for building materials. Class A fireproof materials have good combustion resistance at high temperatures, the flame burns for a long time, the fire is small, and will not spread. This material is suitable for places that require high fire protection, such as fire exits, firewalls, etc.

Class B is a medium fire rating, which requires higher fire performance of materials. Class B fireproof materials can resist burning for a certain period of time at high temperatures, and the fire is small, but the burning time is relatively short. This material is suitable for places where fire protection is generally required, such as indoor partition walls, suspended ceilings, etc.

Class C is a lower fire rating, and the requirements for the fire performance of materials are relatively low. Class C fireproof materials are easy to burn at high temperature, the fire is larger, and the burning time is longer. This material is suitable for places with generally low requirements, such as outdoor partition walls, roofs, etc.

The fire rating calculation of rock wool sandwich panel is mainly carried out through experiments. In the experiment, the sample is placed under specific combustion conditions, and the indicators such as the burning time and the size of the fire are observed. According to the experimental results, the fire rating of the model is divided. The standard of the experiment is carried out with reference to the national standard to ensure the accuracy and reliability of the results.

In addition, the fire rating of the rock wool sandwich panel is also related to its surface material, sandwich material and other factors. Generally speaking, the more flame-retardant the sandwich material of the sandwich panel, the higher its fire rating. Therefore, when choosing a rock wool sandwich panel, attention should be paid to the fire performance of its sandwich material.

In order to improve the fire rating of rock wool sandwich panels, some measures can be taken. For example, paint fire-resistant paint on its surface to increase its resistance to combustion; or add flame retardants to the sandwich material of the sandwich panel to improve its fire-proof performance. These measures can effectively improve the fire rating of rock wool sandwich panels and reduce fire risks.

In short, the fire rating of rock wool sandwich panels is calculated according to national standards, mainly including three grades of A, B and C. The calculation of the fire protection level is carried out through experiments, in which the indicators such as the burning time of the model and the size of the fire are observed. In order to improve the fire rating of rock wool sandwich panels, some measures can be taken, such as painting fire retardant coatings, adding flame retardants, etc. These measures can effectively improve the fire performance of rock wool sandwich panels, reduce fire risks, and ensure the safety of buildings and personnel.