Zhengzhou, Henan Province, China

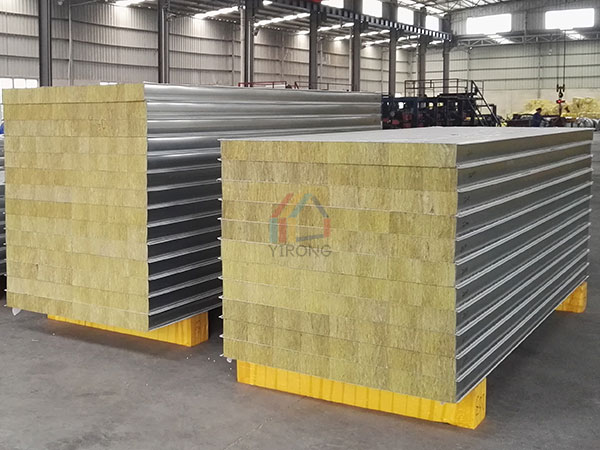

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Rock wool insulation panel is a commonly used building insulation material, which has excellent thermal insulation performance and fireproof performance. When using rock wool insulation panels, you need to pay attention to the following aspects.

1. The installation of rock wool insulation panel should pay attention to the construction environment and conditions. The construction environment should be kept dry to avoid the influence of moisture on the rock wool sandwich panel. The construction conditions should be suitable, and the temperature should not be too low, otherwise the softness of the rock wool board will be reduced, making it difficult to paste and fix.

2. The installation of rock wool insulation panels should pay attention to the treatment and leveling of the base. Base layers such as walls and roofs should be clean and smooth without obvious bumps and cracks. If there is any unevenness, it needs to be repaired and processed to ensure the installation quality of the rock wool insulation board.

3. The fixing of the rock wool insulation board should be firm and reliable. Optionally, it can be fixed with special adhesives and fixings. When applying the adhesive, it is necessary to evenly cover the back of the entire rock wool insulation board to ensure a large bonding area and a good bonding effect. The choice of fixing parts should be reasonable, the quantity should be sufficient, and the tightening should be moderate to avoid damage to the rock wool insulation board.

4. The seams of rock wool insulation panels should be carefully treated. The seams should be sealed with special glue to ensure the heat preservation effect of the seams. The treatment of the seams should be smooth and tight to avoid gaps and air leakage.

When using rock wool insulation panels, you also need to pay attention to the following points.

1. To choose the appropriate rock wool insulation board. Choose rock wool insulation panels of different thicknesses and densities according to actual needs to meet insulation requirements. At the same time, it is necessary to choose products with reliable quality, and avoid buying inferior products, which will affect the insulation effect and service life.

2. Carry out the maintenance and maintenance of the rock wool sandwich panel. Regularly check the installation status of the rock wool insulation panel, and repair and fix it in time if it is damaged or loose. At the same time, pay attention to keep the rock wool insulation panels clean to avoid the accumulation of dust and dirt, which will affect the insulation effect.

3. Pay attention to the fire safety of rock wool insulation panel. The rock wool sandwich panel itself has good fire performance, but fire prevention measures should be paid attention to during the construction process to avoid damage to the rock wool insulation board by open flames and high temperatures.

In short, rock wool insulation board is a high-quality building insulation material. When using it, attention should be paid to the construction environment and conditions, the treatment and leveling of the base, the firm and reliable fixing, and the careful handling of the joints. In addition, it is necessary to choose a suitable rock wool insulation panel, carry out maintenance and maintenance, and pay attention to fire safety. Only by using and maintaining the rock wool insulation panels correctly can it exert its good thermal insulation performance and provide better insulation effect for the building.