Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

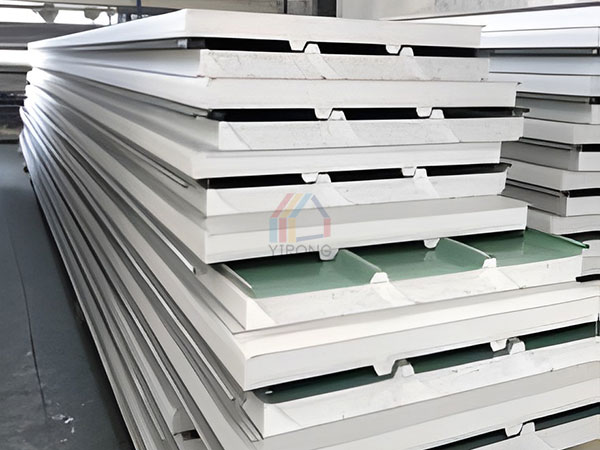

Pir sandwich panel is a high-performance building material that consists of a foam board sandwiched between two layers of different materials. This material is characterized by light weight, heat insulation, fire resistance, water resistance, shock resistance and more. Pir sandwich panels are widely used in construction fields, such as walls, roofs, floors, doors and windows, etc., and are favored for their efficient energy-saving performance. So, how is the pir sandwich panel made? Let's take a closer look below.

1. Raw material preparation

The production of pir sandwich panels requires the preparation of two layers of materials: polyester panels and foam panels. Polyester panel is a building material with good weather resistance and high strength. It is widely used in the field of construction because of its good UV resistance, corrosion resistance, and wear resistance. Foam board is a kind of building material with excellent properties of light weight, heat insulation, fire prevention, waterproof and earthquake resistance. Because of its good heat insulation performance, it is widely used in the field of building insulation.

2. Foam board fabrication

The production of foam boards requires the use of a material called polyisocyanate (pir), which is a polymer material with good physical properties and chemical stability. First, after mixing the polyisocyanate material and other auxiliary materials, it is processed into a foam board by means of high temperature and high pressure. The density and thickness of the foam board can be adjusted according to the needs, generally speaking, the density is 40-45kg/m3, and the thickness is 50-200mm.

3. Sandwich panel production

Sandwich panels are made by sandwiching a foam board between two polyester panels. First, the poly panels are cut to the required size and shape, then the foam board is placed between the two poly panels, pre-positioned to hold them together. Finally, the sandwich panel is sent to a high-temperature and high-pressure machine for processing, making it an integrated building material.

4. Surface treatment

After the sandwich panel is finished, surface treatment is required to improve its aesthetics and waterproof performance. Generally speaking, surface treatment includes three steps: cleaning, spraying primer and spraying topcoat. Cleaning is to remove dust and impurities on the surface of the sandwich panel, spraying primer is to improve the adhesion and waterproof performance of the sandwich panel, and spraying topcoat is to improve the aesthetics of the sandwich panel.

In a word, pir sandwich panel is a high-performance building material, which is composed of polyester panels and foam boards, and has the characteristics of light weight, heat insulation, fire resistance, waterproof, and earthquake resistance. Its production requires steps such as preparing raw materials, making foam boards, sandwich panels, and surface treatment. With the in-depth promotion of the concept of energy saving and environmental protection, the application prospect of pir sandwich panels is very broad.