Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Sandwich Panel

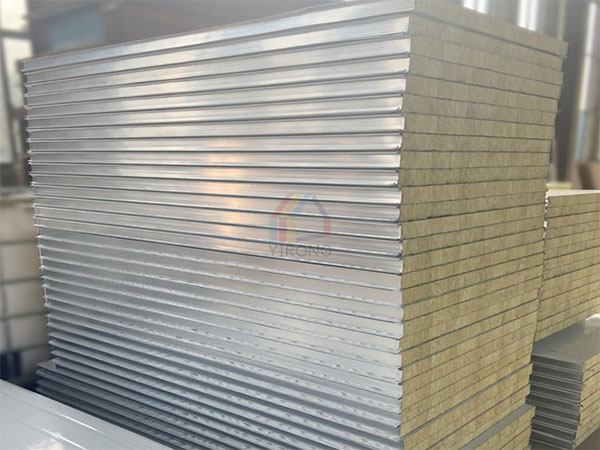

Rock Wool Sandwich Panel

16Jun, 2022

Glass wool sandwich board is a kind of insulation material composed of glass wool, rock wool and foamed plastic. Glass wool insulation board is mainly used for building exterior wall. There are three insulation modes: insulation, external insulation and sandwich insulation. When the external wall is used, it is used in the cavity of the wall, which is densely filled and has outstanding thermal insulation effect.

The new fire-proof glass wool is made of two layers of high-quality color coated steel plates or other precision profiled metal plates. After pressing and forming, turn the divided glass wool 90 degrees (making its fiber perpendicular to the upper and lower layers of steel plates). Through high-strength fire-proof adhesive, the high-quality rock wool is strongly bonded to the metal plate. The formed plate is beautiful, flat, rigid and has excellent fire protection, thermal insulation, environmental protection and other properties. Glass wool sandwich panel is an excellent product choice for industrial building envelope system.

What is glass?

Glass wool belongs to a category of glass fiber, which is a kind of artificial inorganic fiber. Quartz sand, limestone, dolomite and other natural ores are used as the main raw materials, together with some soda ash, borax and other chemical raw materials to melt into glass. In the melting state, with the help of external force blowing, it is thrown into flocculent fine fibers. The fibers and fibers are three-dimensional cross and intertwined with each other, showing many small gaps. This gap can be considered as a pore. Therefore, glass wool can be regarded as porous material with good heat insulation and sound absorption performance.

Glass wool is a kind of inorganic fiber, whose chemical composition belongs to glass It has good molding, small bulk density, good thermal conductivity, thermal insulation, sound absorption, corrosion resistance and stable chemical properties. The main components of mineral wool stone are blast furnace slag, phosphorus slag, fly ash, etc.

Excellent fire resistance

The raw materials, production process and formula of glass sandwich panel make it have good fire resistance. The test shows that it has a fire resistance of more than 1000 ° C.

Good thermal insulation

The thermal insulation performance of the glass sandwich panel is calculated based on the thermal conductivity of the glass wool =0.043w/mk and the thickness of the corresponding proportion of the glass wool core material.

Significant sound absorption and heat insulation

At the same time, the glass sandwich panel has excellent attraction effect. It can absorb sound in a wide frequency range. The sound absorption performance level of glass sandwich panel reaches Delta la=15.7db (a)

Reasonable fastening method

The rock wool roof tile adopts the buckle connection mode, which avoids the hidden danger of water leakage at the roof panel joint and saves the amount of accessories.

| Core material | Glass wool |

| Core density | 64kg/m |

| Effective coverage width | 950mm-1150mm |

| Production thickness | 50/75/100/120/150mm |

| Coating and plating | PE, HDP, PVDF, SMF / Hot-galvanize, Aluminium coating |

| Thermal conductivity | ≤0.042w(m.k) |

| Sound insulation | ≥30db |

| Flammability rating | A |

| Features | Sound insulation, noise reduction, heat preservation, fire prevention |

| Application | External wall thermal insulation and fire prevention of workshop, warehouse and cold storage |

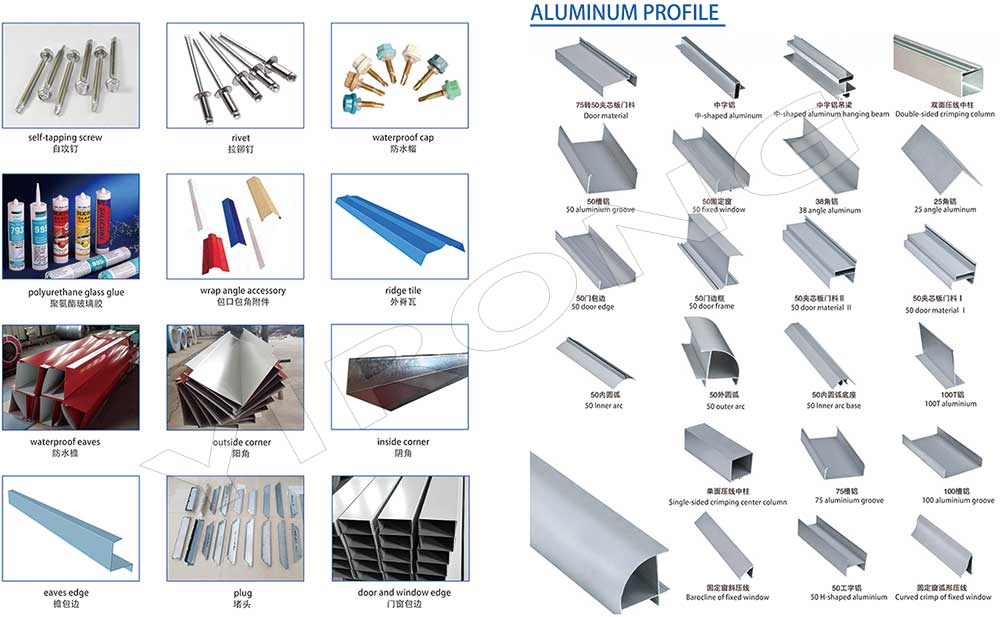

If you purchase metal sandwich panels from Yirong Company, we will also provide some accessory products, including self tapping nails, rivets, waterproof caps, polyurethane glass glue, mouth and corner accessories, outer ridge tiles, waterproof eaves, external and internal corners, eaves edging, plugs, door and window edging, purified aluminum profiles, etc.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged. And all the structure components, panels, bolts and sorts of accessories will be well packed with standard package and it is suitable for ocean transport.

1. Inspection: 50% inline inspection and 100% full final inspection, make sure all output w/o any mistake.

2. Packing: Per customer's requirements or per product sizes, full protection packing.

3. Shipping: Per customer's requirements or per container sizes.

4. Unloading: We package it as a whole and can be easily pulled out at once with a forklift, which is very convenient.