Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

The purlin-free system is becoming more and more popular because of its high economic adaptability, good thermal insulation performance, low material consumption, high utilization rate, and efficient and fast construction. What kind of sandwich panels can be used in the purlin-free system?

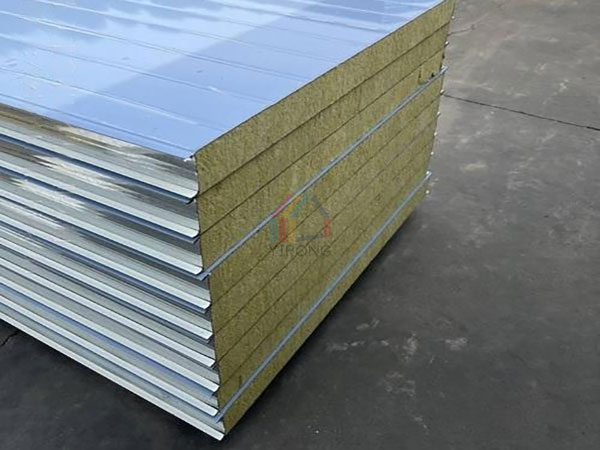

The surface layer of the structural rock wool sandwich panel is color-coated steel plate, and the core material is structural rock wool, which together form a rock wool sandwich panel with excellent mechanical indicators, fire resistance and durability. As the main material of the purlin-free system wall, the rock wool sandwich panel is perfectly matched with the purlin-free system. When it is used as an exterior wall without purlin system, the applicable span/column distance can reach 7-8 meters.

Structural rock wool sandwich panel core material introduction

The structural rock wool sandwich panel core material uses structural rock wool, which is a rock wool core material specially used for the purlin-free sandwich panel. Through a unique formula, the rock wool fiber is processed by a special method, and it is a product specially developed for high-quality sandwich panels. The uniform and dense three-way fiber structure distribution gives each section and direction consistent technical performance, and structural rock wool with the same bulk density has higher strength than ordinary rock wool.

Product Features

1. High strength: It provides nearly twice the mechanical index of ordinary rock wool, and some indexes are more than three times that of the international ones, and the mechanical properties are significantly improved.

2. Heat preservation: High-quality structural rock wool has good dimensional stability, is not easy to shrink and deform, and contributes to long-lasting and stable heat preservation performance.

3. Fire prevention: Non-combustible rock wool, combined with scientific node design, can create a fire-resistant limit plate of up to 4 hours, and can block heat and flame spread.

4. Durability: pass the highest level of ESSC/CIB durability test, providing the basis for the overall durability of the building.

5. Sound insulation: The unique fiber structure is tighter than traditional insulation materials, which can effectively reduce airflow and sound transmission, and can establish an effective barrier to block noise and bring a quieter working environment.

Rock wool sandwich panels are now widely used in building exterior walls because of their light weight, high rigidity, good heat and sound insulation performance, and environmental protection. It is perfectly matched with the purlin-free system, quick to install, and also has a good indoor appearance.