Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Rock wool sandwich panels are of course recyclable. The raw materials of rock wool sandwich panels include natural rock, adhesives, dust-proof oil and metal. Rock wool products in these materials can be better naturally degraded, and metals, etc. have recyclable value.

According to the situation of waste rock wool, the metal and rock wool are separated by a crusher first, and the waste metal is recycled and refined. The separated rock wool is broken into fibers and repressed into blocks. into new rock wool products. The strength and hardness of rock wool briquettes affect the quality and efficiency of reuse. Generally, it needs to be pressed into cylindrical and hexagonal shapes, and the formed block has a certain strength and will not be broken, and can be sent to the kiln for smelting in batches. In order to ensure the quality of the finished product, a process of removing impurities should be carried out before crushing to avoid the entry of other substances.

It should be noted that some leftover materials and rock wool products contaminated by chemical agents should be sent to professional waste factories for waste burial.

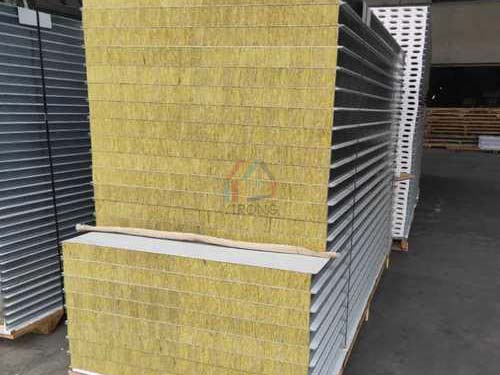

Advantages of rock wool sandwich panels

1. Strong thermal insulation. Rock wool sandwich panels have excellent thermal insulation properties, and are suitable for thermal insulation of construction and industrial equipment, pipes, containers and various kilns. Building insulation prevents heat loss in winter and heat gain in summer.

2. Fire and heat insulation. Metal rock wool sandwich panels have excellent performance in fire protection. The core material is a non-combustible material, and its fire performance far exceeds that of sandwich panels with polyphenylene or polyurethane as the core material.

3. Economical and convenient. The metal rock wool sandwich panel also meets the requirements of the modern construction industry on the economy of building materials and the quickness of construction. The surface of the board has various forms and rich colors. Produced in a highly controlled and constant temperature environment in the factory, the quality is stable. The construction is fast and the loss of materials is reduced, and there is no need for secondary construction on site to save construction time and engineering costs.

4. Green and environmental protection. Metal rock wool sandwich panel is a new type of building material that truly meets the requirements of green environmental protection. The components of the metal rock wool sandwich panel are recyclable, biodegradable, and can be disassembled at any time. Only a small amount of waste is generated during the installation process, and no irritating gas is generated during daily use. The board does not contain formaldehyde, is not attacked by microorganisms, and can be recycled.