Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

With the development of product technology and product requirements in the printing industry and packaging industry, it is necessary to build a clean and dust-free workshop to improve the quality and pass rate of printed products. The construction of a clean room in the printing and packaging industry mainly reflects the temperature and humidity of the product in the coating space environment and the number of dust particles, which directly play an important role in controlling product quality and pass rate. The packaging industry is mainly reflected in the temperature and humidity of the space environment, the number of dust particles in the air, and the quality of water in food packaging and pharmaceutical packaging. In addition, the standardized operation process of production personnel is also very important.

Clean room enclosure structure

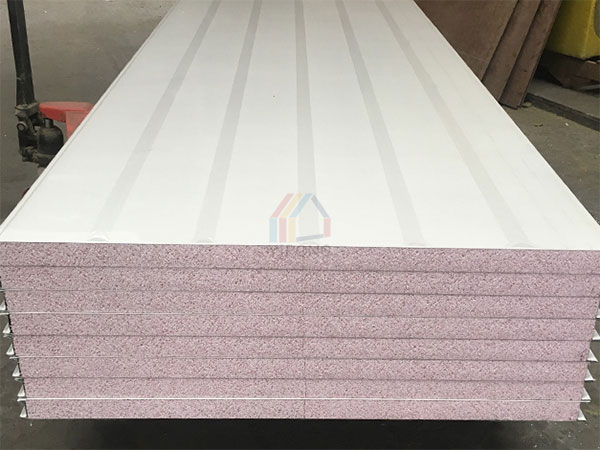

At present, color steel sandwich panels are mostly used in the clean room of printing and packaging factories. During installation, the wall surface adopts tongue-and-groove type, while the ceiling adopts ordinary color steel sandwich panels, and new "single and double" sealed sandwich panels are used to match aluminum profiles. Fasteners and pipelines are concealed in the board. This method makes screws and rivets invisible on the inner wall and ceiling of the clean room, and at the same time improves the airtightness of doors and windows, and uses interlocking and ultraviolet lamp devices in the purification workshop of health care products. The transfer window (cabinet). It can keep the indoor positive pressure stable, prevent pollution, and meet the specification requirements.

The color steel sandwich panels commonly used in clean room are purification panels. Purification panels are classified according to different sandwich materials. There are eps sandwich purification panels, polyurethane purification panels, rock wool purification panels, manual purification panels, and mechanism panels. In the car-free workshop, the purification board we recommend is EPS sandwich board. The purification board made of eps material is light in weight, easy to install, and the price is relatively cheap. If there is no special fire protection requirement, it is more economical and practical to choose eps purification board.