Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

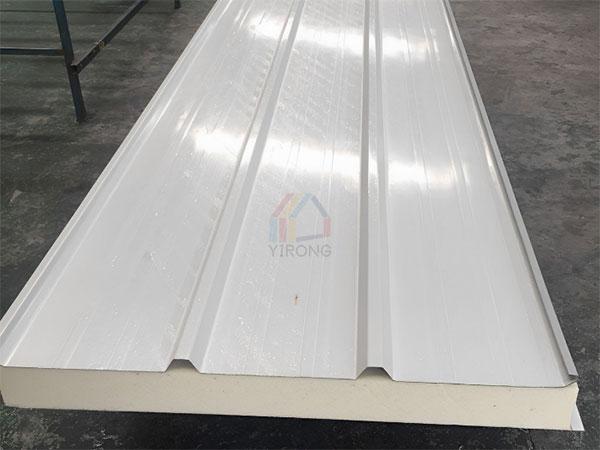

The reason why polyurethane fireproof panel is widely used has a lot to do with its own specifications. Products are divided into thin plates and thick plates according to their thickness, and thick plates are generally used outdoors. Now all steel plates are galvanized, which can greatly improve their corrosion resistance. There are many types of galvanizing, the most commonly used is aluminum zinc.

This special steel plate is made by cold pressing, so it has a certain cold brittleness. However, a lot of alloying elements are added to it, which can make it have a strong load-bearing capacity. Many roofs of common industrial plants are made of polyurethane fireproof panels. The wave height of the material itself is in line with industry standards, ranging from 10-200 mm.

Features of polyurethane fireproof panel

Light weight: 6~14 kg per cubic meter. Easy and flexible installation, no need for large lifting equipment, short construction period and low overall cost.

High bearing capacity: It has the characteristics of high strength and high rigidity, and can be used as both a load-bearing structure and an enclosure structure. The polyurethane thermal insulation sandwich panel has good thermal insulation performance: the average thermal conductivity is 0.023w/(㎡.k).

Good fire performance: tested by the Fireproof Building Materials Quality Supervision and Inspection Center, all tenders have reached B1 level.

Flexible use: due to the use of continuous computer-controlled production lines, the length of polyurethane sandwich panels can be determined according to design requirements and transportation and installation conditions. For different roof loads and purlin distances, different sandwich panel thicknesses can be selected.