Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Sandwich Panel

Color Steel Sheet

16Jun, 2022

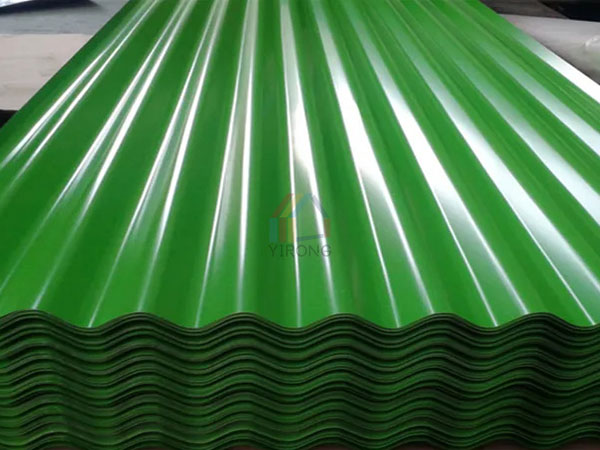

Color steel plate has many advantages such as colorful, rich varieties, complete type plate. The thickness of the color plate substrate adopted by our company must conform to the nationalstandard thickness, all steel plates are hot-dip galvanized steel plate, the thickness of galvanizedis high.

The color steel sheet adopted by our company introduces international famous brand which is an-ti-fade,anti-aging, high temperature resistant special paint, guarantee product quality, the usefullife is more 10 years than ordinary color steel tile.

Color steel tile is a new building material developed by using high-tech chemical technology. It has many excellent characteristics, such as light weight, high strength, waterproof and moisture-proof, anti-corrosion and flame retardant, sound insulation and heat insulation. Color steel sheet is generally applicable to flat to sloping development zones, farmers' markets, shopping malls, residential quarters, high-end villas, awnings, sunshades, etc.

Color steel plate features:

1. Innovative design, multiple colors available.

2. The size can be customized and the water resistance is excellent.

3. Light weight, high strength, durability and strong corrosion resistance.

4. Excellent durability, exquisite material, can maintain the original color for a long time.

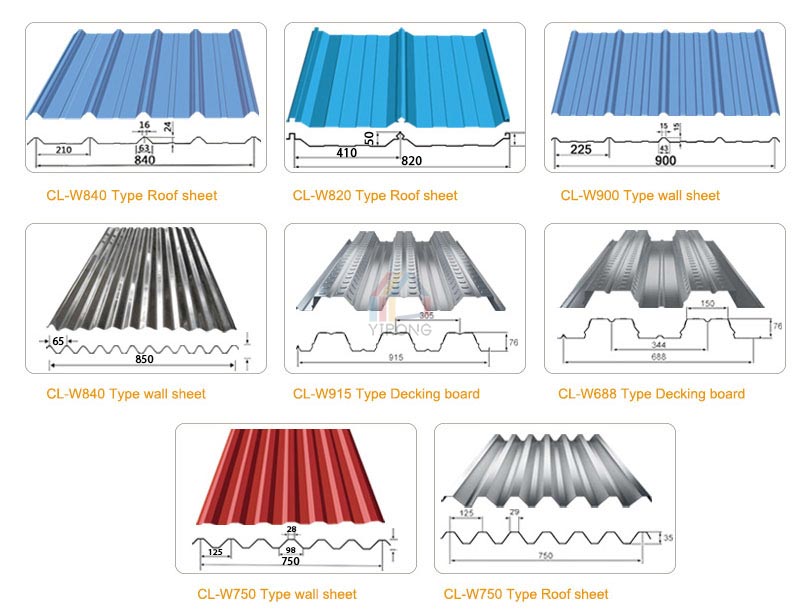

Product parameters:

| Standard: | GB Standard, EU Standard, ASTM Standard, BS Standard |

| Certificates: | CE, ISO9001 |

| Surface Treatment: | Painted & Hot dip galvanized |

| Metal sheet: | Steel sheet / Aluminum plate / PVC |

| Metal sheet thickness: | 0.3-0.8mm |

| Effective width: | 950-1150mm |

| Color coating: | Blue, Green, Red or Custom |

| Length: | Customized or according to transportation conditions |

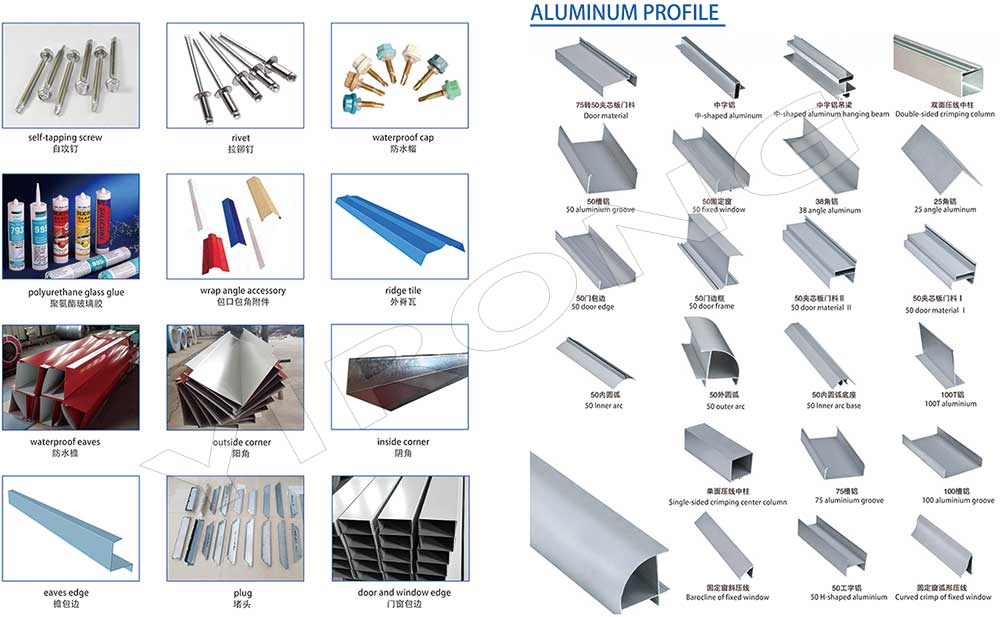

If you purchase metal sandwich panels from Yirong Company, we will also provide some accessory products, including self tapping nails, rivets, waterproof caps, polyurethane glass glue, mouth and corner accessories, outer ridge tiles, waterproof eaves, external and internal corners, eaves edging, plugs, door and window edging, purified aluminum profiles, etc.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged. And all the structure components, panels, bolts and sorts of accessories will be well packed with standard package and it is suitable for ocean transport.

1. Inspection: 50% inline inspection and 100% full final inspection, make sure all output w/o any mistake.

2. Packing: Per customer's requirements or per product sizes, full protection packing.

3. Shipping: Per customer's requirements or per container sizes.

4. Unloading: We package it as a whole and can be easily pulled out at once with a forklift, which is very convenient.