Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Material composition of composite rock wool board:

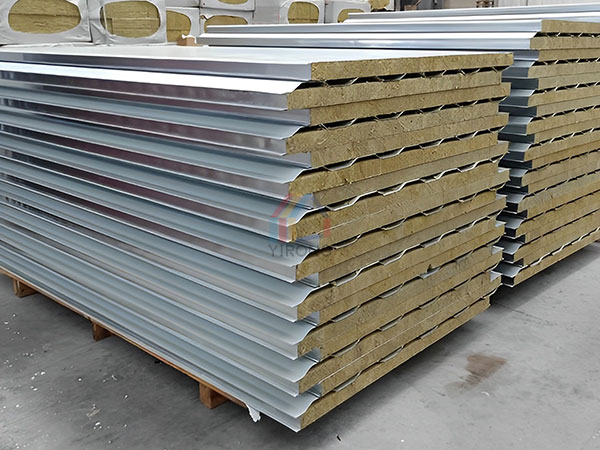

Composite rock wool board is composed of galvanized steel sheet, PVC plastic decorative film, adhesive and rock wool. Specifically, the composite rock wool board is a kind of composite rock wool board which is lined with a certain thickness between two layers of 0.7 mm thick galvanized steel plates. The weight of each square meter of composite rock wool board is 19 kg. The connection form between plates is a type plate and c type plate.

System structure of composite rock wool board:

The system structure of composite rock wool board is mainly composed of bonding layer, thermal insulation layer, plastering layer, finishing layer and accessories.

The bonding layer belongs to the building, which is between the bottom layer and the surface layer. First, the upper and lower layers are firmly bonded together with cementitious materials. The filler is mainly inorganic.

Thermal insulation layer refers to the thermal insulation material layer laid on the outer surface of steam turbine and pipeline to avoid and reduce the heat loss of steam turbine to the environment. The main fillers are rock wool fiber and a certain amount of organic matter, water, adhesive, etc.

The finishing layer shall be light functional coating such as finishing mortar and decorative mortar or water-based exterior wall coating with excellent air permeability, so as to keep the composite rock wool board light and increase its beauty.

The accessories are mainly made of various paints. On the one hand, the color of the surface of the composite rock wool board is increased to make it suitable for any environment. There are also coatings that can be used for flame retardancy and thermal insulation to a certain extent.

Composite rock wool board is a new type of external wall thermal insulation material, which is composed of rock wool board, grid cloth, flexible waterproof mortar and interface agent. It has excellent fire resistance and thermal insulation performance, so it is favored by people in the construction industry. Generally, high-quality composite rock wool board will have the following characteristics: it should have a low thermal conductivity. And composite rock wool fire insulation board process the horizontal fiber of bare rock wool into vertical wire arrangement and lay grid cloth. Special mortar is used for double-sided composite, which enhances the self strength of rock wool and the surface strength of composite rock wool board.

Sound absorbing composite rock wool board is a sound absorbing material composed of rock wool board, perforated board, microporous board, thin board or rock wool board by coating. Because rock wool is an inorganic fiber material, it will always produce fine particles or dust, so the composite rock wool board must be tightly sealed. The utility model has the advantages of hard appearance, convenient modeling, simple construction and high fire protection grade. The sound absorption coefficient depends on the composite method, the thickness of rock wool board and the construction method.