Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

The core material of the drying tunnel board is made of basalt and other natural ores as the main raw materials. The scientific test shows that its fire resistance is very good, with a fire resistance of 600°, a fire rating of A, and a fire resistance time of 80 minutes.

The thermal insulation efficiency range of the drying tunnel board with color steel galvanizing is below 280 degrees. Normally, the furnace body temperature is about 200 degrees, and a drying tunnel plate with a thickness of more than 100mm should be used. The temperature of the furnace body is about 250 degrees, and the thickness of 150mm or more should be used.

The structure of fireproof stainless steel drying tunnel board

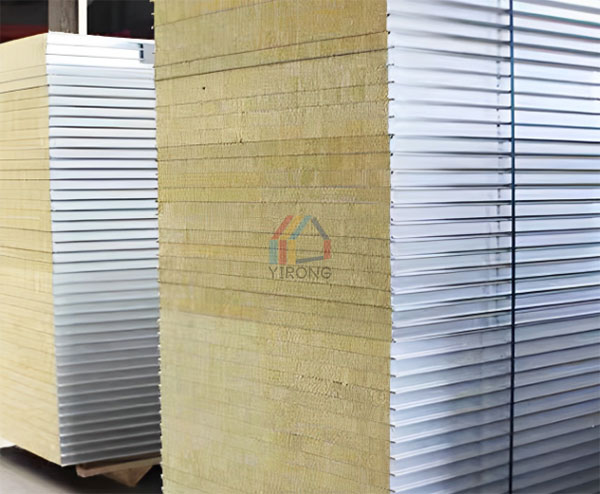

1. Upper and lower surfaces: stainless steel plate with a thickness of 0.4-0.8mm. According to the specific requirements of customers, galvanized color steel plate or galvanized steel plate can also be used. The steel plate is rolled and formed by a forming machine and then compounded with rock wool in the factory.

2. Rock wool core material: The rock wool blocks with a density of 120kg/m³ are interlaced and laid, and the fibers are perpendicular to the upper and lower surfaces of the sandwich panel, and are closely connected to enrich the entire longitudinal and transverse surfaces of the sandwich panel. The rock wool blocks and between the rock wool and the upper and lower steel plates are bonded by high-strength foaming agents to form a whole. The sophisticated production process ensures that the high-density rock wool insulation body and the inner wall of the metal plate can produce extremely Strong adhesive force, so that the rock wool sandwich panel has good rigidity.

The color steel rock wool sandwich panel and its production process realize the compounding of rock wool and steel plate into a whole through automated equipment in the factory, thus changing the previous way of on-site compounding of rock wool panels. On the premise of meeting the requirements of building thermal insulation, sound insulation, fire prevention, etc., it has achieved the goal of high quality and reliability. This product has been widely used in Europe and has matured and perfected.

Application areas of rock wool sandwich panels

Fireproof rock wool board is widely used in steel structure workshop, roof, wall, ceiling and partition of air clean room. Rock wool sandwich panels can generally be customized according to the requirements of customers. Fireproof rock wool board is the most superior fire resistance in the sandwich panel series.