Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Zhengzhou, Henan Province, China

Now Contact: Do you need PU/EPS/Rock Wool sandwich panels?

Sandwich Panel

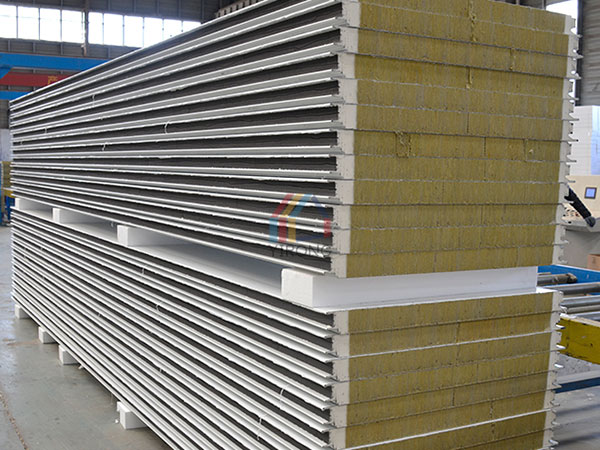

Rock Wool Sandwich Panel

01Jun, 2022

Rock wool panel is a sandwich panel made of rock wool. It is suitable for steel structure workshops, roofs and walls of simple mobile houses, ceilings and partitions of air clean rooms, etc.

The rock wool sandwich panel gives full play to the unique properties of the rock wool core material, and the refractory performance is the most superior among the other sandwich panels. It has significant effects in fire protection, thermal insulation, sound absorption and sound insulation.

1. Width: 950mm/1150mm, the length can be determined according to the design requirements and transportation and installation conditions.

2. Thickness: 50mm 75mm 100mm 120mm 150mm 200mm

【Surface material】 Top/bottom 0.3~0.8mm color coated steel sheet (galvanized sheet, stainless steel sheet, anti-static color coated steel sheet)

Core material

Rock wool density: 60~120kg/m3

Width: 950mm/1150mm

Thickness: 50mm/75mm/100mm/120mm/150mm/200mm

Length: According to project requirements and transportation conditions

Colour: Regularly red/blue/white/grey. Customized according to Ral color card.

1. Best fire resistance: Rock wool sandwich panel has the best fire resistance among other sandwich panels. Tests have shown that it has a fire resistance of over 1000°C.

2. Reasonable buckle connection method: The rock wool roof panel adopts the buckle connection method, which avoids the hidden danger of water leakage in the joints of the roof panel and saves the amount of accessories.

3. The fixing method is firm and reasonable: the rock wool roof panel is fixed with special colored self-tapping screws and purlins, which can effectively resist the action of external forces such as typhoons. The self-tapping screw is set at the crest position on the upper surface of the roof panel, and adopts a special waterproof structure to avoid weak points of waterproofing.

4. Short installation period: Because the rock wool sandwich panel does not need secondary processing on site, it can not only keep the surrounding environment clean and tidy, without affecting the normal operation of other processes, but also greatly shorten the installation period of the board.

5. Anti-scratch protection: During the production of rock wool sandwich panels, polyethylene self-adhesive protective film can be pasted on the surface to avoid scratches or abrasions on the surface coating of the steel plate during transportation and installation.

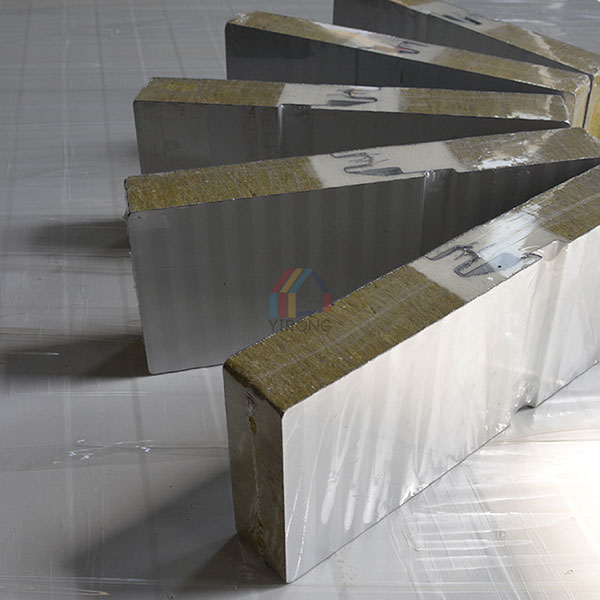

1. Upper and bottom surfaces: galvanized color steel plate with a thickness of 0.3-0.8mm. According to the specific requirements of customers, galvanized color steel plate or galvanized steel plate can also be used. The steel plate is first rolled and formed by a forming machine and then compounded with a rock wool factory.

2. Rock wool core material: Rock wool blocks with a density of 60-120KG/m3 are interlaced and laid, and the fibers are perpendicular to the upper and lower surfaces of the sandwich panel, and are closely connected to enrich the entire longitudinal and transverse surfaces of the sandwich panel. The rock wool blocks and between the rock wool and the upper and lower steel plates are bonded together by a high-strength foaming agent to form a whole. Strong adhesive force, so that the rock wool sandwich panel has good rigidity.

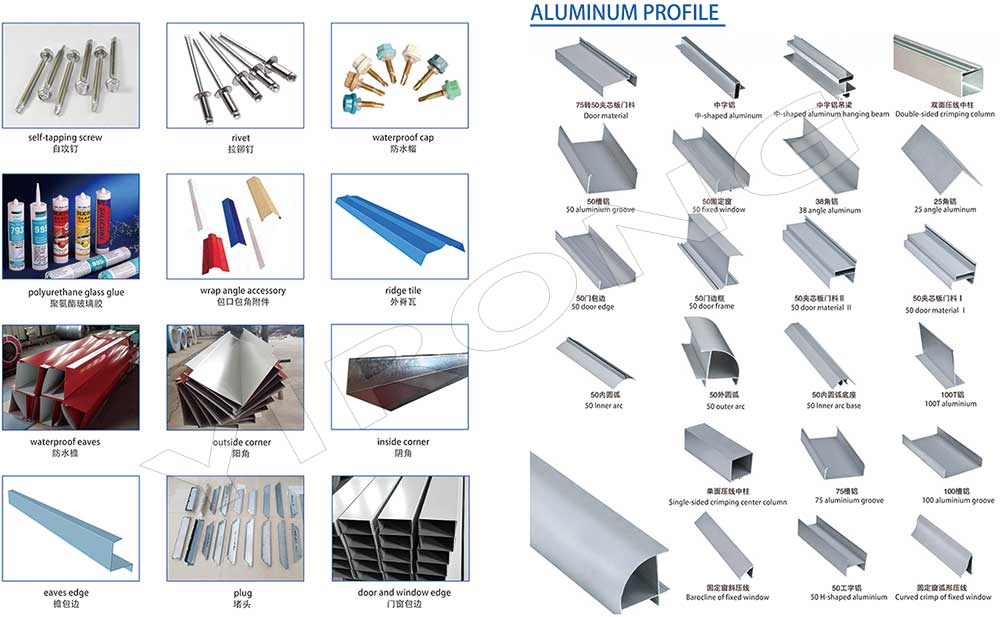

If you purchase metal sandwich panels from Yirong Company, we will also provide some accessory products, including self tapping nails, rivets, waterproof caps, polyurethane glass glue, mouth and corner accessories, outer ridge tiles, waterproof eaves, external and internal corners, eaves edging, plugs, door and window edging, purified aluminum profiles, etc.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged. And all the structure components, panels, bolts and sorts of accessories will be well packed with standard package and it is suitable for ocean transport.

1. Inspection: 50% inline inspection and 100% full final inspection, make sure all output w/o any mistake.

2. Packing: Per customer's requirements or per product sizes, full protection packing.

3. Shipping: Per customer's requirements or per container sizes.

4. Unloading: We package it as a whole and can be easily pulled out at once with a forklift, which is very convenient.